Navigating the Supply Chain Planning Certificate Program

Supply chain management is all about making sure things move smoothly from the makers to the buyers. And planning is a big part of making that happen well. So, if you’re interested in being great at this, getting certified in supply chain planning with KnoWerX can be a smart move. This article covers everything you need to know about it, like what it is, how to get it, what kind of jobs you can get, how much it costs, and some final thoughts to consider.

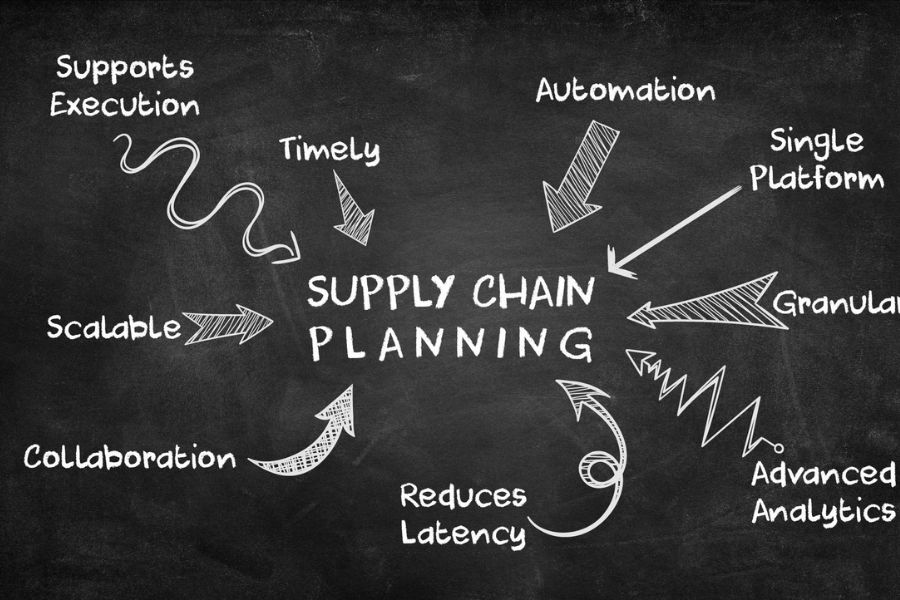

What Is Supply Chain Planning?

Supply chain planning is all about making sure things move smoothly from one point to another in a business’s supply chain. This includes figuring out how much stuff is needed, when it’s needed, and how to get it where it needs to go efficiently. It involves predicting what customers will want, managing how much stuff is kept in storage, scheduling when things are made, and figuring out the best ways to transport everything.

Good supply chain planning helps companies meet customer needs without wasting resources or money. It’s important because it helps businesses match what they make and buy with what customers want, and with what they can do. By knowing what customers are likely to want and keeping just enough stuff on hand, companies can avoid running out of products or having too much leftover. This keeps customers happy and saves money.

Also, supply chain planning helps companies make smarter decisions by giving them information about how to best use their resources, when to make things, and how to move them around efficiently.

What Is A Supply Chain Planning System?

A supply chain planning system is like a computer program that helps companies plan and manage their supply chain activities. It pulls together information from different places to help predict things like how much demand there will be for products, how much inventory to keep, and how to make decisions about production and transportation.

These systems have special features that help with things like predicting demand, figuring out the best way to manage inventory, planning production schedules, and managing transportation.

Using a supply chain planning system helps companies work more efficiently. They can use fancy math and analysis to make smarter decisions, cut down on the time it takes to get products to customers, and adapt quickly when things change in the market. These systems also make it easier for different teams within a company, as well as outside partners, to work together and stay on the same page.

Supply Chain Planning Process

The process of planning your supply chain usually has a few steps that are all connected:

Forecasting Demand: This means trying to predict how much of your product or service people will want in the future. You look at things like past sales, what’s happening in the market, and other important info.

Planning Inventory: Figuring out how much stuff you should have in stock to meet demand without having too much or too little. You want to avoid running out of stock and also don’t want to be stuck with too much stuff that you can’t sell.

Organizing Production: Making a schedule for when you’ll produce your goods. This schedule should match up with what you expect people will want to buy and what resources you have available.

Sorting out Distribution: Deciding the best way to move your products from where they’re made to where they’re sold. This involves getting things to distribution centers and then to customers efficiently.

Working Together in the Supply Chain: This is about collaborating with everyone involved in making and selling your product. That means talking with suppliers, manufacturers, distributors, and others to make sure everyone is on the same page and things run smoothly.

Supply Chain Planning Examples

There are many examples of smart supply chain planning strategies used in different industries:

Just-in-Time (JIT) Manufacturing: Toyota came up with this idea. Instead of making a lot of stuff and keeping it in a warehouse, they only make things when they’re needed. This saves money on storing things for a long time.

Cross-Docking: Big stores like Walmart do this. They have special places called cross-docking facilities. These places help to move things from the suppliers to the stores quickly. It means they don’t have to keep stuff in the warehouse for too long.

Vendor-Managed Inventory (VMI): In VMI, suppliers keep an eye on how much stuff is in the stores and fill it up when it’s running low. This helps make sure there’s always enough stuff in the store without wasting too much. It’s like having someone take care of your shopping list for you.

Supply Chain Planning Jobs

Professionals who specialize in supply chain planning have a variety of career options available to them, such as:

Supply Chain Analyst: This role involves examining data, forecasting future trends, and finding ways to improve the efficiency of supply chain processes.

Demand Planner: Demand planners predict how much of a product will be needed, manage inventory levels, and work closely with different teams to make sure products are available when customers want them.

Supply Chain Manager: In this position, individuals are responsible for overseeing the entire supply chain process, from start to finish. They implement long-term strategies, make sure everything runs smoothly, and allocate resources effectively.

How To Get a Supply Chain Planning Certificate?

To Get a Supply Chain Planning Certificate, you’ll typically follow these steps:

Choosing the Right Certificate: First things first, you want to find a Certificate program that’s well-respected in the field. Look into popular choices like the APICS Supply Chain Planning Certificate. This Certificate is highly valued and trusted by professionals. Also, check out what KnoWerX has to offer—they provide courses for supply chain planning certificates too.

Meet Eligibility Requirements: Each program will have its own set of requirements. These might include having a certain level of education, relevant work experience, or completing specific training courses. Make sure you meet these prerequisites before moving forward.

Prepare for the Exam: Once you’re eligible, it’s time to get ready for the Certificate exam. This means studying the material that will be covered in the exam, attending any review courses available, and practicing with sample questions or exam simulations. The goal is to make sure you’re fully prepared for what’s going to be tested.

Pass the Certificate Exam: The big day arrives when you take the Certificate exam. This is where you’ll demonstrate your understanding of supply chain planning concepts and principles. If you’ve done your preparation well, you should feel confident going into the exam.

Supply Chain Certificate Cost

The price of getting certified in supply chain planning can differ based on a few things like which Certificate you go for, the fees for exams, study stuff, and training sessions. Typically, people might end up spending anywhere from a few hundred to several thousand dollars to get certified. But it’s worth noting that the payoff in terms of better job opportunities and higher salaries can be quite big.

End Notes

In wrapping up, we firmly believe that obtaining a Certificate in supply chain planning can significantly benefit professionals aiming to thrive in the ever-evolving realm of supply chain management. Through acquiring the necessary knowledge, honing essential skills, and attaining recognized credentials, individuals can elevate their career prospects, contribute meaningfully to their organizations’ achievements, and maintain a competitive edge in the global arena. Whether aspiring to roles as supply chain analysts, planners, managers, or executives, embarking on the Certificate journey demands unwavering dedication, persistence, and a steadfast commitment to continuous learning.

At KnoWerX, we understand that embracing the fundamental principles of supply chain planning holds the power to empower both individuals and organizations. By cultivating an environment where complex challenges are met with innovative solutions, we strive to equip our students with the tools they need to navigate today’s interconnected world successfully. Our mission is to facilitate sustainable growth and foster a culture of excellence in supply chain management, ensuring that our graduates emerge as leaders capable of driving positive change in their respective industries.

FAQs: Frequently Asked Questions

What is a supply chain planning Certificate?

A. A supply chain planning Certificate is a professional credential that validates expertise in strategic coordination, forecasting, demand planning, inventory management, and logistics optimization within the supply chain domain.

Why is supply chain planning important?

A. Supply chain planning is crucial for optimizing processes, reducing costs, and enhancing competitiveness by ensuring efficient movement of goods and services from suppliers to customers.

What are the key components of a supply chain planning system?

A. A supply chain planning system typically includes demand forecasting algorithms, inventory optimization models, production planning tools, transportation management capabilities, and data integration functionalities.

How can supply chain planning benefit businesses?

A. Effective supply chain planning enables businesses to align production, procurement, and distribution processes with market demand, reduce inventory holding costs, minimize stockouts, and improve customer satisfaction.