Types of Supply Chain Risks and Effective Mitigation Strategies | KnoWerX

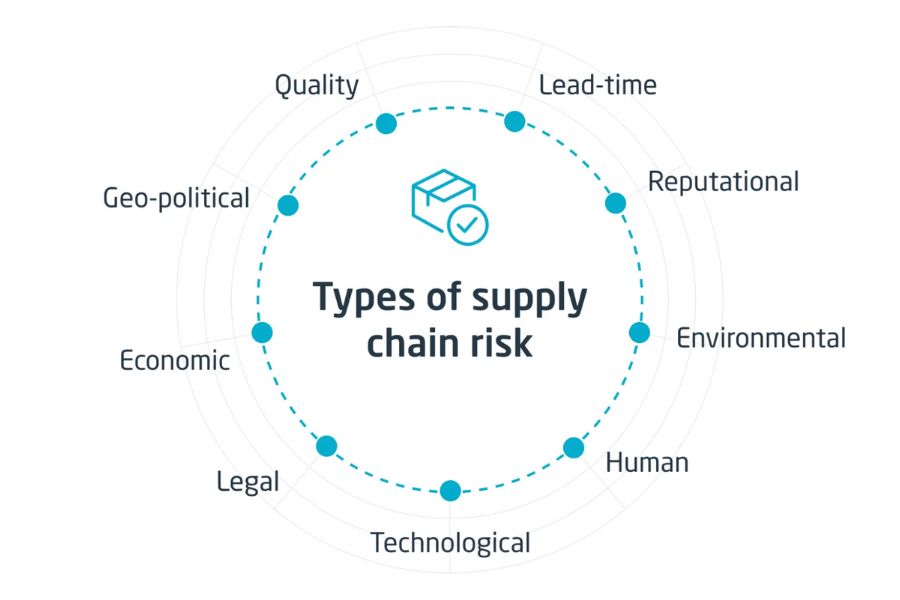

In today’s globalized business environment, supply chains are more complex and interconnected than ever before. Managing these supply chains effectively is crucial for business success, and understanding the types of supply chain risks is a fundamental part of this process. Supply chain risks can disrupt operations, increase costs, and damage a company’s reputation. Therefore, identifying and mitigating these risks is essential for maintaining a smooth and resilient supply chain.

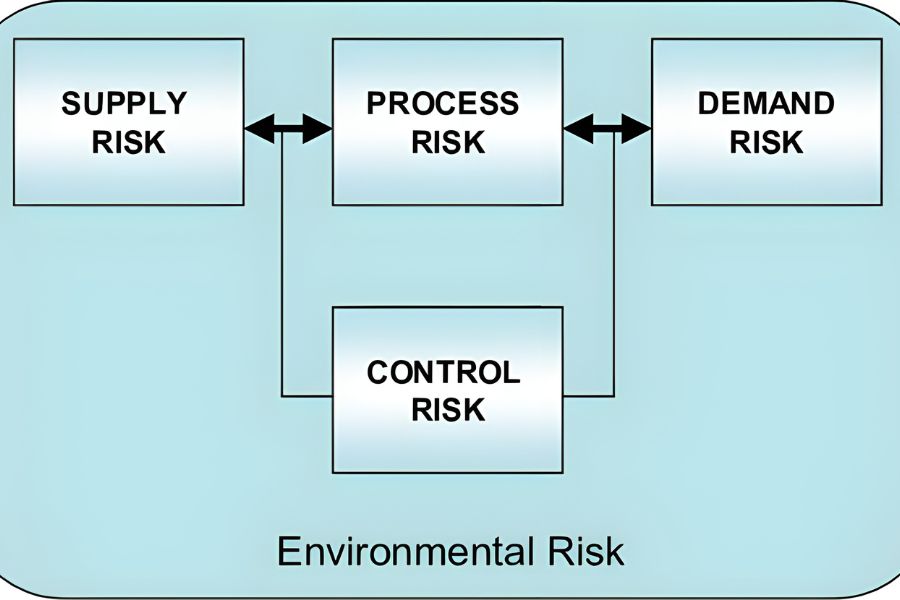

Operational Risks

Operational risks are among the most common types of supply chain risks. These risks arise from day-to-day operations and can significantly impact the efficiency and effectiveness of a supply chain.

Definition and Examples of Operational Risks

Operational risks include any disruptions in the processes that move products from suppliers to customers. Examples include equipment failures, supply shortages, transportation delays, and quality control issues. For instance, if a key supplier experiences a machinery breakdown, it can halt production and delay deliveries, impacting the entire supply chain.

Causes of Operational Risks

The causes of operational risks are diverse. They can originate from internal challenges such as poor equipment maintenance, or external factors like labour strikes at supplier locations. Additionally, natural disasters and accidents can trigger these types of supply chain risks, resulting in unforeseen delays and interruptions.

Strategies to Mitigate Operational Risks

Mitigating operational risks requires proactive planning and robust strategies. Companies should implement contingency plans to address potential disruptions. This includes having backup suppliers, maintaining safety stock, and using real-time monitoring systems to track supply chain activities. Diversifying suppliers and sourcing from multiple regions can also help reduce the impact of local disruptions.

Financial Risks

Financial risks are another critical type of supply chain risk that can affect a company’s profitability and stability.

Definition and Examples of Financial Risks

Among the types of supply chain risks, financial risks specifically relate to economic factors that can destabilize a supply chain’s financial foundation. Common examples include currency fluctuations, interest rate variations, cost overruns, and supplier bankruptcies. For instance, a sudden currency devaluation can escalate the cost of imported goods, thereby squeezing profit margins.

Causes of Financial Risks

Several factors can cause financial risks. These include volatile currency markets, fluctuating commodity prices, and changes in trade policies. Economic downturns and financial instability in supplier regions can also pose significant financial risks.

Strategies to Mitigate Financial Risks

To mitigate financial risks, companies can employ strategies such as hedging against currency fluctuations and locking in prices with long-term contracts. Regular financial monitoring and analysis can help identify potential risks early. Building strong relationships with financial institutions and diversifying investment portfolios can also provide a buffer against financial uncertainties.

Strategic Risks

Strategic risks are types of supply chain risks that arise from changes in the business environment and strategic decisions.

Definition and Examples of Strategic Risks

Strategic risks include any factors that can alter the competitive landscape or affect long-term business goals. Examples are market changes, new regulations, and shifts in consumer preferences. For instance, a new regulatory policy might require changes in product formulations, affecting the entire supply chain.

Causes of Strategic Risks

The causes of strategic risks are often external and beyond a company’s control. These include geopolitical developments, technological advancements, and changing market dynamics. Strategic decisions, such as entering new markets or launching new products, can also introduce risks.

Strategies to Mitigate Strategic Risks

Mitigating strategic risks involves thorough market research and continuous monitoring of the business environment. Companies should stay informed about regulatory changes and industry trends. Developing flexible business strategies and maintaining agility in operations can help adapt to changes quickly. Engaging in scenario planning and stress testing can also prepare companies for potential strategic risks.

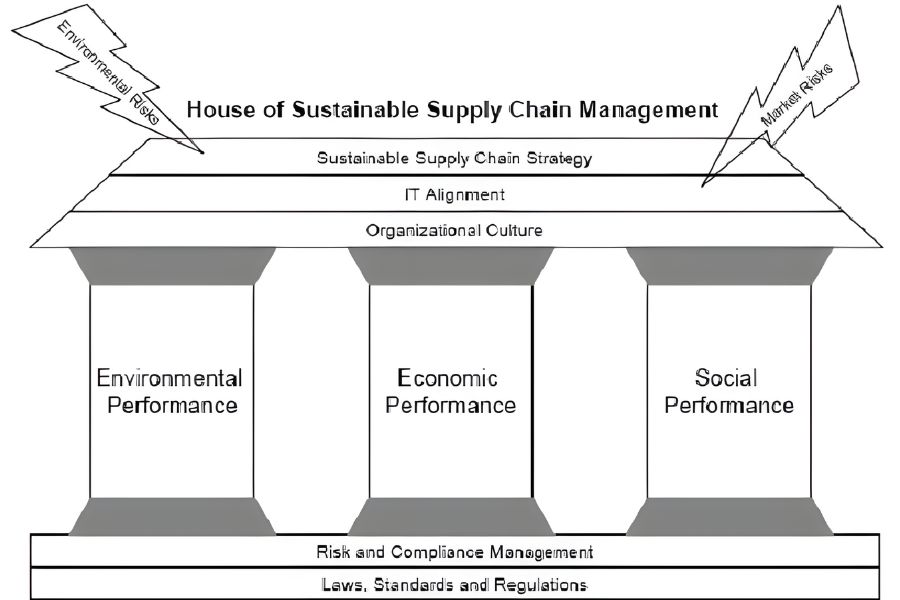

Environmental Risks

Environmental risks are types of supply chain risks that arise from environmental factors and natural events.

Definition and Examples of Environmental Risks

Environmental risks encompass any natural or environmental factors that can disrupt supply chains. Examples include natural disasters like earthquakes, floods, hurricanes, and climate change impacts. For instance, a hurricane can damage infrastructure and halt transportation, severely affecting supply chain operations.

Causes of Environmental Risks

Environmental risks are typically caused by natural events and changes in environmental conditions. Climate change is increasing the frequency and severity of extreme weather events, posing significant risks to supply chains. Environmental regulations and sustainability pressures also contribute to these risks.

Strategies to Mitigate Environmental Risks

To mitigate environmental risks, companies should adopt sustainability practices and build resilience into their supply chains. This includes conducting environmental impact assessments, investing in disaster recovery plans, and diversifying supply chain routes to avoid high-risk areas. Collaborating with suppliers to enhance their environmental resilience is also crucial.

Technological Risks

Technological risks are types of supply chain risks associated with technology and information systems.

Definition and Examples of Technological Risks

Technological risks involve threats related to the use of technology in supply chains. Examples include cybersecurity threats, technology failures, and data breaches. For instance, a cyber-attack on a supplier’s system can compromise sensitive information and disrupt supply chain operations.

Causes of Technological Risks

Technological risks can arise from various sources, including outdated systems, inadequate cybersecurity measures, and rapid technological changes. Human errors and insufficient training on new technologies can also lead to technological risks.

Strategies to Mitigate Technological Risks

Mitigating technological risks requires robust cybersecurity measures and regular system updates. Companies should invest in secure IT infrastructure and conduct regular security audits. Implementing comprehensive training programs for employees and establishing protocols for technology management can also reduce the risk of technological disruptions.

Geopolitical Risks

Geopolitical risks are types of supply chain risks that arise from political instability, conflicts, and government actions.

Definition and Examples of Geopolitical Risks

Geopolitical risks involve disruptions caused by political events or changes in government policies. Examples include trade wars, embargoes, sanctions, and political instability in supplier countries. For instance, a trade war between two countries can lead to increased tariffs, affecting the cost and availability of goods.

Causes of Geopolitical Risks

The causes of geopolitical risks are diverse and can include diplomatic disputes, changes in government, civil unrest, and military conflicts. Government actions such as the nationalization of industries or sudden regulatory changes can also introduce geopolitical risks.

Strategies to Mitigate Geopolitical Risks

Mitigating geopolitical risks requires a thorough understanding of the global political landscape and the ability to adapt to changes. Companies should diversify their supply bases across multiple countries to reduce reliance on any single region. Establishing strong relationships with local partners and staying informed about political developments can also help manage these risks. Scenario planning and developing contingency plans are essential for anticipating and responding to geopolitical events.

Regulatory Risks

Regulatory risks are types of supply chain risks that arise from changes in laws, regulations, and compliance requirements.

Definition and Examples of Regulatory Risks

Regulatory risks involve the potential for new or changing regulations to impact supply chain operations. Examples include new environmental regulations, labour laws, and safety standards. For instance, a new regulation requiring stricter emissions controls can necessitate changes in production processes, affecting the supply chain.

Causes of Regulatory Risks

Regulatory risks are typically caused by government actions and policy changes. These can be influenced by political shifts, public pressure, or international agreements. Sudden changes in regulations can catch companies off guard, leading to non-compliance issues and potential penalties.

Strategies to Mitigate Regulatory Risks

To mitigate regulatory risks, companies must stay informed about regulatory developments and engage in proactive compliance management. This includes conducting regular audits, training staff on compliance requirements, and maintaining open communication with regulatory bodies. Developing flexible operational strategies that can quickly adapt to regulatory changes is also crucial.

Market Risks

Market risks are types of supply chain risks that arise from changes in market conditions and consumer behaviour.

Definition and Examples of Market Risks

Market risks involve the potential for changes in market demand, competition, and consumer preferences to impact supply chains. Examples include sudden shifts in consumer trends, the entry of new competitors, and changes in market demand. For instance, a sudden drop in demand for a product can lead to excess inventory and financial losses.

Causes of Market Risks

The causes of market risks are often external and can include economic downturns, changes in consumer behaviour, and competitive pressures. Advances in technology and innovation can also lead to market disruptions, changing the competitive landscape.

Strategies to Mitigate Market Risks

Mitigating market risks requires a deep understanding of market dynamics and the ability to adapt to changes quickly. Companies should invest in market research and analytics to anticipate changes in consumer behaviour and market conditions. Diversifying product offerings and maintaining flexible production capabilities can help manage market fluctuations. Developing strong customer relationships and enhancing brand loyalty are also important for mitigating market risks.

Supply Chain Network Risks

Supply chain network risks are types of supply chain risks that arise from the structure and complexity of the supply chain itself.

Definition and Examples of Supply Chain Network Risks

Supply chain network risks involve disruptions that occur within the supply chain network due to its complexity and interdependencies. Examples include bottlenecks in production, misalignment between supply chain partners, and disruptions in logistics. For instance, a delay at a single node in the supply chain can create a ripple effect, causing delays throughout the entire network.

Causes of Supply Chain Network Risks

The causes of supply chain network risks are often related to the design and management of the supply chain. Complex and poorly coordinated supply chains are more susceptible to disruptions. Lack of visibility and communication between supply chain partners can also contribute to these risks.

Strategies to Mitigate Supply Chain Network Risks

Mitigating supply chain network risks requires improving coordination and visibility across the supply chain. Companies should invest in supply chain management technologies that provide real-time data and analytics. Building strong relationships with suppliers and logistics providers and fostering collaboration can also enhance supply chain resilience. Simplifying the supply chain network and reducing dependencies on single points of failure are important strategies for managing these types of supply chain risks.

Supplier Risks

Supplier risks are types of supply chain risks that arise from the performance and reliability of suppliers.

Definition and Examples of Supplier Risks

Supplier risks involve disruptions caused by supplier-related issues. Examples include supplier bankruptcies, poor quality control, and delivery delays. For instance, if a key supplier fails to meet quality standards, it can lead to product recalls and reputational damage.

Causes of Supplier Risks

The causes of supplier risks are varied and can include financial instability, lack of capacity, and poor management practices. Geographic location and exposure to environmental and geopolitical risks can also affect suppliers.

Strategies to Mitigate Supplier Risks

To mitigate supplier risks, companies need to conduct thorough evaluations and regular assessments of supplier performance and financial stability. Building strong relationships and maintaining open communication with suppliers can help identify and address potential issues early. Furthermore, diversifying the supplier base and developing contingency plans for critical suppliers are crucial strategies for managing these types of supply chain risks.

Demand Risks

Demand risks are types of supply chain risks that represent a critical concern for businesses striving to meet customer expectations while optimizing resources.

Definition and Examples of Demand Risks

Demand risks refer to uncertainties and potential fluctuations in consumer demand that can impact a company’s ability to meet its production, inventory, and distribution objectives. These risks can lead to various challenges, such as stockouts, overstock situations, and inefficient resource allocation.

Causes of Demand Risks

Rapid changes in market conditions, driven by economic shifts or geopolitical events, can create demand uncertainty. Issues such as transportation delays, production interruptions, or supplier problems can affect the ability to meet demand, leading to either excess inventory or shortages.

Strategies to Mitigate Demand Risks

Mitigating demand risks requires a combination of proactive planning, flexibility, and strategic management. Develop a flexible supply chain that can quickly adjust to changes in demand. This may involve maintaining relationships with multiple suppliers or having flexible production capabilities. Just-in-Time JIT inventory systems can help reduce excess stock and minimize holding costs, though they require precise demand forecasting and reliable suppliers.

FAQs: Frequently Asked Questions

What are supply chain risks?

Supply chain risks refer to potential disruptions or challenges within the supply chain that can impact a company's operations, costs, or reputation. These risks can arise from various factors, including operational issues, financial instability, or environmental factors.

What are operational risks in supply chains?

Operational risks in supply chains are disruptions in day-to-day processes, such as equipment failures, supply shortages, or transportation delays, that can affect the flow of goods from suppliers to customers.

How can companies mitigate financial risks in supply chains?

Companies can mitigate financial risks by employing strategies like hedging against currency fluctuations, locking in prices with long-term contracts, and regularly monitoring financial conditions to identify potential risks early.

What are environmental risks in supply chains?

Environmental risks involve natural events or environmental factors, such as natural disasters or climate change, that can disrupt supply chains. Companies can mitigate these risks by adopting sustainability practices and disaster recovery plans.

What is KnoWerX's Supply Chain Risk and Resiliency (SCRR) course?

KnoWerX's SCRR course is designed to equip professionals with the knowledge and skills needed to identify, assess, and mitigate various supply chain risks, helping businesses build resilient and efficient supply chains.

End Notes

At KnoWerX, we emphasize that understanding and managing the various types of supply chain risks is essential for building a resilient and efficient supply chain. From operational and financial risks to strategic, environmental, technological, geopolitical, regulatory, market, supply chain network, and supplier risks, each presents unique challenges that require targeted mitigation strategies. Our approach integrates proactive planning, continuous monitoring, and adaptive strategies to effectively navigate these risks.

Our Supply Chain Risk and Resiliency (SCRR) course at KnoWerX is designed to equip professionals with the knowledge and skills needed to manage these diverse risks. By staying ahead of emerging risks and implementing robust risk management practices, companies can enhance their supply chain resilience, maintain operational continuity, and gain a competitive edge.

As global supply chains evolve, so do the risks associated with them. Whether through leveraging advanced technology, cultivating strong supplier relationships, or conducting strategic market analysis, proactively addressing these risks is crucial for fostering a sustainable and adaptable supply chain. At KnoWerX, we provide the expertise and tools necessary to help businesses build and sustain resilient supply chains in the face of any challenges.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.