Inventory Management Certification in the Supply Chain Industry

Inventory management plays a critical role in the efficiency and success of supply chain operations. It involves the strategic handling of goods and materials, ensuring the right products are available in the right quantities at the right time. This article explores the significance of inventory management within the supply chain industry and the importance of obtaining certification in this field.

What Is Inventory Management?

Inventory management is all about keeping track of, controlling, and making the most out of the stuff a company has and needs. It involves a bunch of tasks like figuring out how much stuff to have, guessing what the company will need later on, buying new things, storing them, and getting them to where they’re supposed to be. When done right, it helps companies have just enough stuff to meet what customers want, while also not having too much extra stuff that costs a lot.

The main goal of inventory management is to find the right balance between how much stuff is available and how much is needed. By figuring out what customers will want and having the right amount of stuff, companies can avoid running out of things, spend less on storing stuff, and work more smoothly overall. Especially in today’s fast-moving business world, where what customers want changes a lot, having good inventory management is super important for staying competitive and keeping customers happy.

What Is The Scope Of Inventory Management?

Inventory management is all about making sure a company handles its goods smoothly and effectively. Here’s what it covers:

- Demand Forecasting: Predicting future demand for products based on historical data, market trends, and other relevant factors. Accurate demand forecasting is essential for ensuring that sufficient inventory is available to meet customer needs without excess or stockouts.

- Stock Control: Implementing strategies to regulate the quantity and movement of inventory within warehouses or distribution centers. This involves setting reorder points, safety stock levels, and implementing inventory tracking systems to monitor stock levels in real-time.

- Inventory Optimization: Inventory Optimization is all about making inventory work better for your business. It’s about finding ways to spend less money on storing inventory, making sure you don’t run out of stock, and getting items moving faster. We do this by using smart techniques like figuring out which items are most important (ABC analysis), calculating the best order quantities (EOQ), and using systems that deliver items just when we need them (JIT). These tricks help us save money, keep shelves stocked, and keep things flowing smoothly.

What Is Required For Inventory Management?

Achieving success in inventory management roles requires a combination of skills, qualifications, and personal attributes. Key requirements include:

- Analyzing Stuff: Inventory managers need to be good at looking at data, figuring out patterns, and using that info to decide how much stuff we need to keep, buy, or move around.

- Tech Savvy: They should be comfortable using computer programs made for inventory, like those fancy systems big companies use to keep track of everything they’ve got.

- Knowing How Things Flow: They need to understand how things move through a business, from buying stuff to getting it to customers. It’s like knowing how pieces fit together in a puzzle.

- Talking and Listening: They need to be able to talk to different people, like suppliers who bring in stuff or folks in the warehouse moving things around. Good communication helps make sure everyone knows what’s going on.

- Paying Close Attention: Details matter! They should be eagle-eyed when it comes to checking how much stuff is there and noticing if something’s not quite right.

- Fixing Problems: When things go wrong, they need to be like detectives, figuring out why and finding solutions, whether it’s running out of stuff or having too much.

- Getting Certified: Obtaining certification such as the CIMO (Certified Inventory Management Officer) offered by KnoWerX can significantly enhance one’s expertise in inventory management. While not obligatory, this certification demonstrates a deep understanding of inventory management principles and techniques, potentially broadening job prospects for individuals in the field

So, by learning these skills, understanding how things move in a business, and maybe getting some extra training, folks can set themselves up for success in inventory management. It’s all about keeping things organized and running smoothly in the ever-changing world of supply chains.

How To Become An Inventory Manager

- Educational Background: Start by getting a degree in something like supply chain management, logistics, business administration, or a similar field. This lays down the groundwork for understanding inventory management.

- Relevant Experience: It’s important to get hands-on experience. Look for internships or entry-level jobs in areas like inventory control, procurement, or logistics. This helps you learn the ins and outs of managing inventory.

- Keep Learning: Take additional courses or attend workshops focused on inventory management. This shows that you’re committed to learning and improving your skills.

- Get Certified: Consider getting certified in inventory management. There are certifications like CIMO (Certified Inventory Management Officer) that show you’ve mastered the practices of inventory management.

- Network: Build connections within the supply chain industry. This can open doors to mentorship opportunities and job openings in inventory.

By following these steps, you can work your way towards becoming a successful inventory manager!

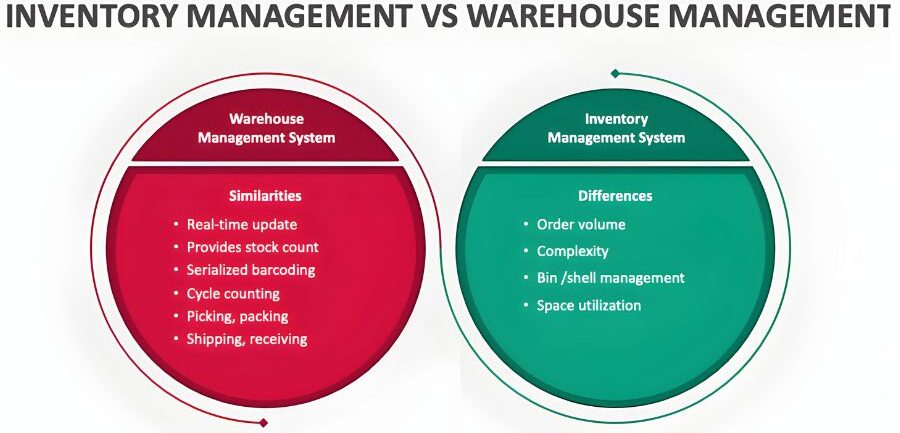

Inventory Management Vs Warehouse Management

Inventory management and warehouse management are both crucial parts of making sure things run smoothly in supply chains, but they handle different jobs.

Inventory Management:

- This is about finding the right balance of stuff you have in stock. You want enough to satisfy customers without having too much and wasting money on storage or risking running out.

- It involves figuring out how much you’ll need, when you’ll need it, and making sure you have just the right amount at the right time.

Warehouse Management:

- This one deals with the physical side of things – where you actually keep all that stuff.

- It’s about making sure everything is organized in the warehouse so you can find it easily, moving things around efficiently, and keeping track of what comes in and what goes out.

Think of it like this: Inventory management decides how much of each item you need, while warehouse management is all about making sure those items are stored, moved, and tracked properly within the warehouse.

Best Certification For Inventory Management

When it comes to proving your skills in handling inventory effectively, getting certified can be a big help. Here are top certification that employers really value:

Certified Inventory Management Officer (CIMO): CIMO certification, offered by KnoWerX Education, promises to deliver skilled, certified, and competent professionals in the industry segment. The content of CIMO and all other courses from KnoWerX are based on the latest industry practices.

This certification proves that you’ve got the skills to handle inventory like a pro. It is great for boosting your resume and showing employers you’re serious about making their inventory management top-notch.

Inventory Management Courses In India

In India, the field of supply chain management is rapidly changing, creating a growing need for professionals who are skilled in managing inventory. At KnoWerX, we understand this demand very well. That’s why we’ve developed the CIMO (Certified Inventory Management Officer) Program. Our program covers a variety of important topics necessary for effective inventory management. We delve into inventory control techniques, material handling, warehouse management, inventory managing strategies, and optimization methods. Our main focus is to improve participants’ understanding of inventory control systems, demand planning, and inventory optimization techniques. We aim to prepare them for success in today’s evolving supply chain environment. Our Upcoming event for CIMO (Certified Inventory Management Officer) is beginning from 15th June 2024.

End Notes

Here at KnoWerX, we think that getting certified in inventory management can make a big difference for Individuals who want to do well in supply chain management. Our course CIMO (Certified Inventory Management Officer) covers everything you need to know and gives you the certifications to prove you are capable enough at handling inventory. Whether you’re just starting in inventory management or you want to get better at what you already do, it’s super important to keep learning and growing with our programs. That way, you’ll stay ahead in today’s tough business world.

FAQs : Frequently Asked Question

What are the primary responsibilities of an inventory manager?

A. The main job of an inventory manager is to keep an eye on how much stuff a company has, make sure the records are correct, and figure out the best ways to use and buy more stuff. They work with other teams to guess how much stuff will be needed and to make sure everything runs smoothly.

Can I pursue an inventory management certification without prior experience in supply chain management?

A. You don’t always need to have worked in supply chain management before getting a certification in inventory. Some programs like CIMO are designed to teach you everything you need to know, no matter your background.

How long does it typically take to complete an inventory management certification program?

A. How long it takes to finish an inventory management certification can change depending on the program and how fast you learn. Some might only take a few months, while others could last a year or even more.

Are there any ongoing requirements to maintain an inventory management certification?

A. Once you’ve got your certification, you usually have to keep it up by doing more learning or taking tests every so often. This helps make sure you stay updated on the latest stuff in inventory management.