Enhance Your Supply Chain Efficiency: Effective Tips & Solutions

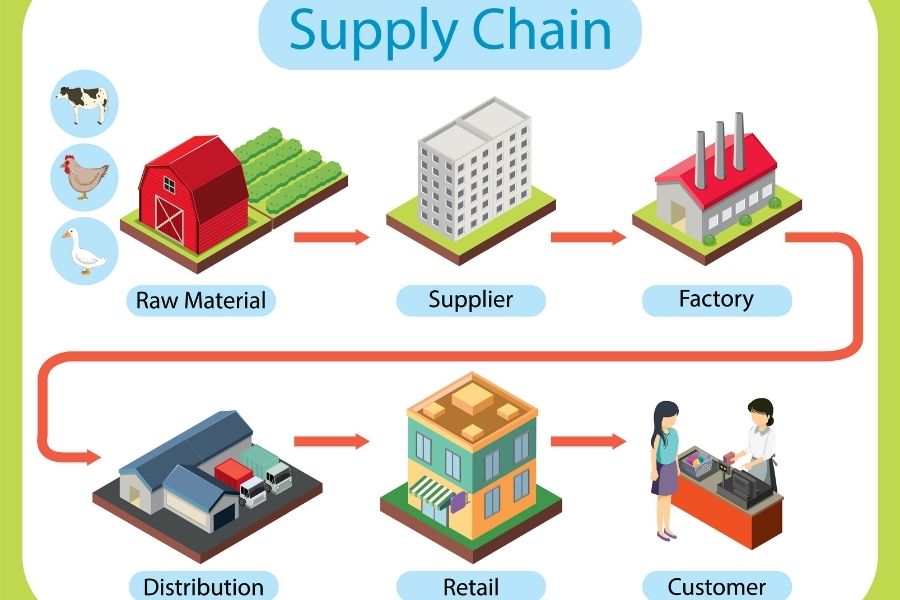

Supply chain efficiency refers to the effectiveness with which a company manages its supply chain processes, including procurement, production, transportation, and delivery, to minimise costs and maximise productivity. At KnoWerX, we emphasise teaching the seamless integration of these processes, ensuring the timely and optimal delivery of products to customers. Efficiency in the supply chain is not solely about speed; it involves crafting a streamlined, reliable, and cost-effective system that boosts overall business performance.

Importance in Today’s Business Landscape

In today’s highly competitive business environment, supply chain efficiency is crucial. It directly impacts a company’s bottom line by reducing operational costs, improving customer satisfaction, and increasing overall profitability. Companies with efficient supply chains can respond more quickly to market changes, manage risks better, and maintain a competitive edge. As global markets continue to evolve, the importance of supply chain efficiency cannot be overstated. It is a key differentiator that can make or break a business.

Assess Current Supply Chain Performance

Key Performance Indicators (KPIs)

To improve supply chain efficiency, it is essential first to assess the current performance. This can be done by tracking key performance indicators (KPIs) such as order accuracy, delivery times, inventory turnover, and supply chain costs. These metrics provide a clear picture of where the supply chain stands and highlight areas needing improvement. Common KPIs include:

- Order Fulfillment Cycle Time: The total time taken from receiving an order to delivering the product to the customer.

- Perfect Order Rate: The percentage of orders delivered without any issues, such as delays, inaccuracies, or damage.

- Inventory Turnover Ratio: The number of times inventory is sold and replaced over a specific period.

- Supply Chain Cost per Unit: The total cost incurred in the supply chain process is divided by the number of units handled.

Identifying Bottlenecks and Inefficiencies

Once KPIs are measured, the next step is identifying bottlenecks and inefficiencies. These can occur at various points in the supply chain, such as production delays, transportation issues, or inventory mismanagement. Identifying these problem areas is crucial for developing targeted improvement strategies. By using techniques such as process mapping and root cause analysis, businesses can uncover hidden inefficiencies and develop actionable plans to address them, thereby boosting supply chain efficiency.

Implement Advanced Technology

Supply Chain Management Software

Advanced technology plays a significant role in enhancing supply chain efficiency. Supply chain management (SCM) software helps streamline operations by providing real-time data, improving communication, and automating various processes. This software can manage everything from procurement to delivery, ensuring a smooth flow of goods and information. Features of SCM software include:

- Real-Time Inventory Tracking: Monitoring inventory levels across multiple locations in real-time.

- Order Processing Automation: Automating order processing to reduce manual errors and speed up order fulfillment.

- Supplier Management: Managing supplier relationships and performance through a centralized platform.

Internet of Things (IoT) and Real-Time Tracking

The Internet of Things (IoT) allows for real-time tracking of products and assets throughout the supply chain. IoT devices can monitor conditions such as temperature and humidity, ensuring that goods are handled correctly. Real-time tracking also provides visibility into the movement of products, helping to prevent delays and losses. Applications of IoT in supply chain efficiency include:

- Asset Tracking: Using IoT sensors to monitor the location and condition of assets such as vehicles, containers, and equipment.

- Environmental Monitoring: Ensuring that perishable goods are stored and transported under optimal conditions.

- Predictive Maintenance: Using data from IoT devices to predict and prevent equipment failures before they occur.

Artificial Intelligence and Predictive Analytics

Artificial Intelligence (AI) and predictive analytics can analyze vast amounts of data to forecast demand, optimize inventory levels, and identify potential disruptions before they occur. These technologies enable companies to make data-driven decisions, enhancing efficiency and reducing costs. Examples of AI applications in supply chain efficiency include:

- Demand Forecasting: Using machine learning algorithms to predict future demand based on historical data and market trends.

- Inventory Optimization: Automatically adjusting inventory levels based on predicted demand and current stock levels.

- Risk Management: Identifying potential risks and disruptions in the supply chain and developing mitigation strategies.

Optimize Inventory Management

Just-in-Time (JIT) Inventory

Just-in-time (JIT) inventory management reduces waste and storage costs by receiving goods only as they are needed in the production process. This approach minimizes inventory holding costs and reduces the risk of overstocking or stockouts. Implementing JIT requires close coordination with suppliers and a deep understanding of demand patterns. When done correctly, JIT can significantly enhance supply chain efficiency by aligning inventory levels with actual consumption.

Demand Forecasting Techniques

Accurate demand forecasting is crucial for maintaining optimal inventory levels. By using historical data, market trends, and predictive analytics, companies can anticipate customer demand more accurately, ensuring that they have the right products in the right quantities at the right time. Effective demand forecasting reduces the likelihood of stockouts and overstock situations, contributing to supply chain efficiency by optimizing inventory turnover and reducing holding costs.

Supplier Relationship Management

Building strong relationships with suppliers is essential for efficient inventory management. Reliable suppliers can provide high-quality materials on time, reducing production delays and ensuring a steady supply of goods. Effective supplier relationship management involves regular communication, performance reviews, and collaborative planning. By fostering strong partnerships with suppliers, companies can improve supply chain efficiency through better coordination, reliability, and responsiveness.

Streamline Transportation and Logistics

Route Optimization

Efficient transportation is a key component of a streamlined supply chain. Route optimization software can analyse various factors such as traffic, delivery schedules, and fuel costs to determine the most efficient routes. This reduces transportation time and costs while ensuring timely deliveries. Route optimization enhances supply chain efficiency by minimizing delays and maximizing resource utilization, ultimately leading to faster and more reliable delivery of goods.

Carrier Selection and Management

Selecting the right carriers and managing relationships with them is critical for effective logistics. Companies should evaluate carriers based on their reliability, cost, and service quality. Regular performance assessments and maintaining open communication with carriers can help ensure consistent and efficient delivery. By choosing the best carriers and fostering strong relationships, businesses can enhance supply chain efficiency through improved service levels and cost management.

Multi-Modal Transportation Strategies

Utilizing multi-modal transportation strategies, which combine different modes of transport such as road, rail, air, and sea, can enhance flexibility and reduce costs. This approach allows companies to choose the most efficient and cost-effective transportation methods for different stages of the supply chain. Multi-modal transportation strategies enhance supply chain efficiency by providing more options and flexibility in meeting delivery schedules and managing transportation costs.

Enhance Warehouse Operations

Layout and Design Optimization

Optimizing the layout and design of warehouses can significantly improve supply chain efficiency. This includes organizing storage areas to minimize movement, implementing efficient picking and packing processes, and using technology such as warehouse management systems (WMS) to track inventory and streamline operations. Strategies for optimizing warehouse layout and design include:

Storage Zoning: Organizing storage areas based on factors such as product type, turnover rate, and size to minimize movement and improve efficiency.

Efficient Picking and Packing: Implementing efficient picking and packing processes to reduce time and labour costs.

Warehouse Management Systems (WMS): Using WMS technology to track inventory, manage orders, and optimize warehouse operations.

Workforce Training and Management

A well-trained and managed workforce is essential for efficient warehouse operations. Providing regular training on new technologies and processes, fostering a culture of continuous improvement, and implementing performance incentives can boost productivity and ensure smooth operations. Strategies for workforce training and management include:

Regular Training Programs: Providing regular training on new technologies, processes, and best practices to keep employees up-to-date and skilled.

Performance Incentives: Implementing performance incentives such as bonuses and recognition programs to motivate employees and improve productivity.

Continuous Improvement Culture: Fostering a culture of continuous improvement by encouraging employees to identify and implement process improvements.

Foster Collaboration and Communication

Internal Team Alignment

Aligning internal teams, including procurement, production, and logistics, is crucial for efficient supply chain management. Regular meetings, clear communication channels, and shared goals can ensure that all teams work together towards common objectives. By fostering internal alignment, businesses can improve supply chain efficiency through better coordination, reduced errors, and faster decision-making.

Supplier and Customer Integration

Integrating suppliers and customers into the supply chain process can enhance collaboration and efficiency. This involves sharing information, collaborating on demand forecasting, and working together on inventory management. Strong partnerships with suppliers and customers can lead to improved coordination and reduced lead times. Supplier and customer integration enhances supply chain efficiency by creating a more responsive and interconnected supply chain network.

Data Sharing and Transparency

Transparent data sharing across the supply chain is vital for informed decision-making. Implementing systems that allow for real-time data sharing between all stakeholders can improve visibility, enhance collaboration, and reduce the risk of errors and delays. By fostering data transparency, businesses can enhance supply chain efficiency through better communication, faster problem resolution, and more accurate planning.

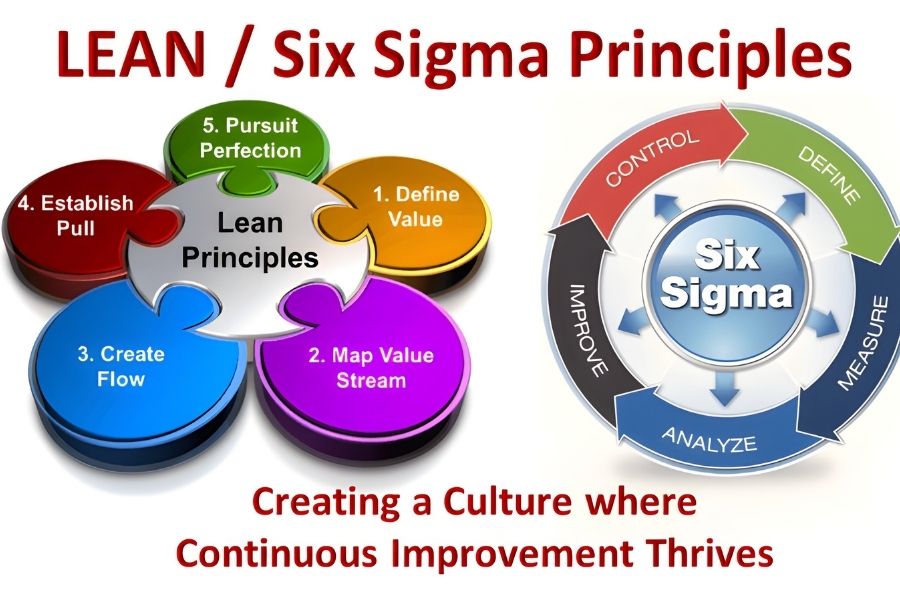

Continuous Improvement and Lean Principles

Six Sigma Methodology

The Six Sigma methodology focuses on reducing defects and variability in processes. By using data-driven techniques and statistical analysis, companies can identify and eliminate inefficiencies, leading to improved supply chain performance. Implementing Six Sigma principles enhances supply chain efficiency by driving process improvements and ensuring consistent quality.

Kaizen Events

Kaizen events are focused, short-term projects aimed at improving specific processes. These events involve cross-functional teams working together to identify problems, develop solutions, and implement changes. Regular Kaizen events can drive continuous improvement and enhance overall supply chain efficiency. By fostering a culture of continuous improvement, businesses can maintain high levels of supply chain efficiency and adaptability.

Regular Performance Reviews and Adjustments

Continuous improvement requires regular performance reviews and adjustments. Companies should regularly evaluate their supply chain performance, using KPIs and other metrics, and make necessary adjustments to processes and strategies to maintain efficiency. By conducting regular reviews and making data-driven adjustments, businesses can ensure ongoing supply chain efficiency and responsiveness to changing conditions.

Sustainable Supply Chain Practices

Reducing Waste and Emissions

Sustainable supply chain practices involve reducing waste and emissions throughout the supply chain. This includes optimizing transportation routes, reducing packaging waste, and implementing energy-efficient practices in warehouses and production facilities. By adopting sustainable practices, businesses can enhance supply chain efficiency by reducing costs and environmental impact.

Ethical Sourcing

Ethical sourcing ensures that materials are obtained in a responsible and sustainable manner. This includes considering the environmental and social impacts of sourcing decisions, working with suppliers who adhere to ethical practices, and supporting fair labour practices. Ethical sourcing enhances supply chain efficiency by building a more sustainable and resilient supply chain network.

Circular Economy Principles

Implementing circular economy principles involves designing products and processes that minimize waste and maximize resource use. This includes recycling, reusing, and repurposing materials, as well as designing products for longevity and ease of repair. Circular economy principles enhance supply chain efficiency by creating closed-loop systems that reduce waste and increase resource efficiency.

Education and Training

Continuous Learning and Development

At KnoWerX, we understand that investing in education and training for employees is crucial for maintaining supply chain efficiency. Our continuous learning and development programs are designed to ensure that employees stay up-to-date with the latest technologies, best practices, and industry trends. Our strategies for continuous learning and development include:

- Training Programs: We offer regular training programs on new technologies, processes, and best practices to keep our members at the forefront of supply chain management.

- Certifications: We encourage supply chain professionals to obtain relevant certifications, such as Six Sigma, APICS and KnoWerX’s Certification to enhance their professional credentials and expertise.

- Workshops and Seminars: We host workshops and seminars that provide our members with opportunities to learn from industry experts and stay informed about the latest developments in supply chain management.

Leadership Development

At KnoWerX, developing strong leaders within the supply chain is essential for driving efficiency and continuous improvement. Our leadership development programs focus on building the skills and capabilities of supply chain leaders to effectively manage teams, drive change, and achieve strategic goals. Our strategies for leadership development include:

- Mentorship Programs: We pair emerging leaders with experienced mentors to provide guidance and support, helping them grow into effective supply chain leaders.

- Leadership Training: We offer training programs that focus on essential leadership skills, such as decision-making, communication, and strategic thinking, to prepare our members for leadership roles.

- Succession Planning: We develop succession plans to ensure a pipeline of capable leaders for future supply chain roles, supporting long-term organizational success.

Cross-Training and Skill Diversification

At KnoWerX, we believe that cross-training employees and diversifying their skills can enhance supply chain efficiency by increasing flexibility and resilience. Our cross-training programs enable employees to perform multiple roles, reducing the impact of absences and improving overall productivity. Our strategies for cross-training and skill diversification include:

- Job Rotation: We implement job rotation programs that allow employees to gain experience in different roles within the supply chain, broadening their skill sets and understanding of the entire process.

- Skill Development: We offer training programs focused on developing a diverse set of skills, such as project management, data analysis, and process improvement, to equip our members with the tools they need for success.

- Employee Engagement: We encourage our members to take on new challenges and responsibilities to develop their skills and capabilities, fostering a culture of continuous improvement and professional growth.

At KnoWerX, we are dedicated to providing top-notch education and training to help our members excel in the ever-evolving field of supply chain management.

FAQs: Frequently Asked Questions

What is supply chain efficiency?

Supply chain efficiency refers to the effectiveness of managing supply chain processes to minimize costs and maximize productivity, ensuring the timely and optimal delivery of products.

Why is supply chain efficiency important in today's business landscape?

Supply chain efficiency is crucial as it reduces operational costs, improves customer satisfaction, and increases profitability. Efficient supply chains help companies respond quickly to market changes, manage risks better, and maintain a competitive edge.

How can advanced technology improve supply chain efficiency?

Advanced technologies like supply chain management software, IoT, and AI can streamline operations, provide real-time data, enhance communication, and automate processes, leading to improved efficiency and reduced costs.

How does KnoWerX support supply chain efficiency through education and training?

KnoWerX offers continuous learning and development programs, certifications, workshops, and seminars to keep supply chain professionals up-to-date with industry trends and best practices, enhancing their expertise and efficiency.

End Notes

At KnoWerX, we believe that enhancing supply chain efficiency necessitates a holistic strategy encompassing several key areas. These include evaluating current performance, leveraging advanced technologies, optimizing inventory management, refining transportation and logistics, improving warehouse operations, fostering collaboration, and committing to continuous improvement, relevant education and training and sustainable practices. Each of these elements plays a vital role in creating a more efficient and effective supply chain.

By adopting these strategies, companies can achieve long-term benefits such as reduced costs, improved customer satisfaction, increased profitability, and a competitive edge in the market. Investing in supply chain efficiency is not only beneficial for immediate gains but also crucial for sustaining success in today’s dynamic business landscape. Enhanced supply chain efficiency leads to a more agile, responsive, and resilient business, capable of thriving in the face of challenges and opportunities.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.