Why Material Requirement Planning Transforms Efficiency

At KnoWerX, we understand that in a dynamic manufacturing environment, having the right materials in the right place at the right time is not just essential—it’s transformative. Material Requirement Planning (MRP) is more than a concept; it’s a strategic tool that reshapes how businesses manage inventory, production schedules, and overall operational efficiency. As customer expectations grow and competition intensifies, MRP becomes a critical advantage, allowing companies to meet demand efficiently, avoiding both overstock issues and costly production delays.

So, what exactly is MRP, and how can it drive such significant gains in efficiency? Let’s explore how this powerful system works and why KnoWerX considers it fundamental for any business seeking to streamline operations, reduce costs, and remain competitive.

What is Material Requirement Planning?

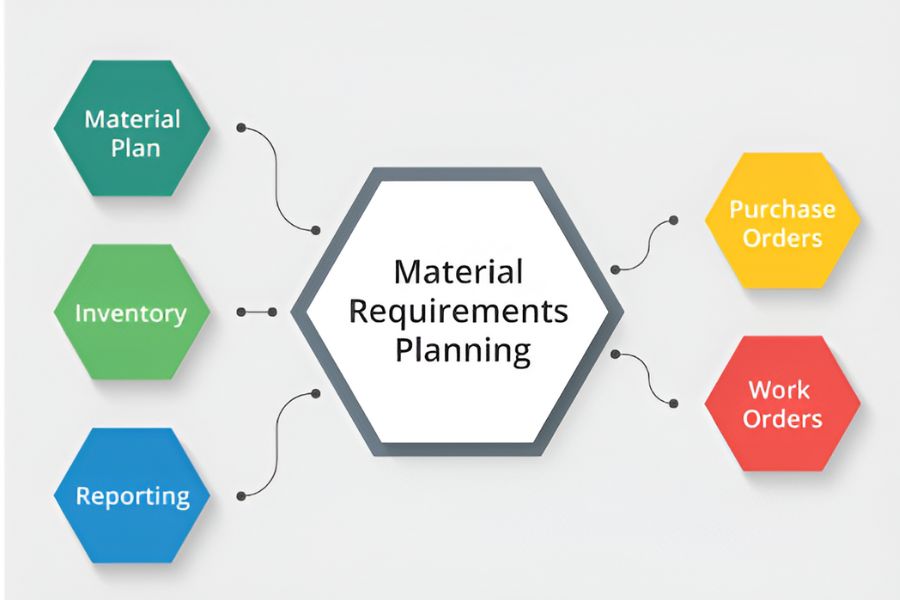

Material Requirement Planning (MRP) is a systematic approach to ensure that materials and components required for production are available when needed. Think of it as a blueprint for balancing supply with demand. MRP uses data from sales forecasts, inventory levels, and production schedules to calculate the exact amount of raw materials required and the timing for when they should be ordered.

In essence, MRP helps answer three critical questions for manufacturers:

- What materials are needed?

- How much of each material is required?

- When should these materials be available?

By streamlining these processes, MRP enables companies to avoid the pitfalls of either running out of materials or overstocking, which can lead to higher costs and wasted resources.

Key Benefits of Material Requirement Planning

MRP is more than just a scheduling tool; it’s a transformative approach that provides several key benefits. Let’s explore how MRP directly impacts efficiency and improves various aspects of production management.

1. Reduces Inventory Costs

One of the major benefits of MRP is its ability to lower inventory costs. By determining precisely when materials are required, MRP allows companies to maintain lean inventories. Businesses don’t need to hold excessive stock, which ties up capital and takes up storage space. Instead, MRP helps manage stock levels in real-time, ordering just enough material to meet production needs and maintain flexibility.

2. Improves Production Scheduling

MRP ensures that production schedules align seamlessly with material availability. It helps avoid situations where production must halt due to missing materials or delays in supply. By planning ahead and predicting requirements accurately, companies can keep production lines running smoothly, minimizing downtime and maximizing productivity. Improved scheduling also leads to better use of labour, reducing overtime and enhancing worker productivity.

3. Enhances Customer Satisfaction

In manufacturing, meeting customer deadlines is crucial. MRP improves order fulfilment by ensuring that products are ready on time, which strengthens customer satisfaction and trust. With reliable MRP in place, companies can promise timely deliveries, adjust quickly to demand changes, and maintain a competitive edge in the market.

4. Boosts Overall Operational Efficiency

Efficiency isn’t just about cutting costs; it’s about ensuring that every part of the production process works in harmony. MRP automates much of the planning process, reducing the time spent on manual calculations and allowing production managers to focus on high-priority tasks. This efficiency cascades through the entire operation, from ordering raw materials to final product delivery, creating a streamlined production cycle that saves time and resources.

5. Facilitates Better Decision-Making

MRP provides critical data insights that support smarter, data-driven decisions. By analyzing demand forecasts and inventory trends, MRP systems allow managers to make informed decisions about production volumes, inventory levels, and resource allocation. In turn, this helps businesses reduce waste, minimize costs, and respond swiftly to shifts in market demand.

How Does Material Requirement Planning Work?

Material Requirement Planning operates by using three main inputs to calculate material requirements:

- Master Production Schedule (MPS): This is a plan for producing specific products at specific times.

- Bill of Materials (BOM): A comprehensive list of raw materials and components needed for each product.

- Inventory Status Records: Current stock levels and location of materials within the warehouse.

By analyzing these inputs, MRP systems calculate precise material requirements and generate recommendations for purchase orders or production actions. Advanced MRP systems even incorporate predictive analytics, which can enhance planning accuracy by factoring in potential demand fluctuations or supplier lead times.

Challenges in Implementing MRP

While MRP offers immense benefits, implementing it does come with its challenges. Companies may face issues like:

- Data Accuracy: MRP relies heavily on accurate data inputs. Errors in inventory records or production schedules can lead to incorrect material orders or scheduling issues.

- Complexity and Training: MRP software can be complex, requiring skilled personnel to manage and interpret data effectively.

- Integration with Other Systems: For MRP to work effectively, it should integrate smoothly with existing inventory and production management software.

Companies often overcome these challenges by investing in employee training, regularly updating data, and working with MRP software providers to ensure seamless integration.

The Future of Material Requirement Planning

The future of MRP is promising, especially with advances in digital technology. Modern MRP systems now incorporate AI and machine learning, which provide more accurate demand forecasts and can adapt to changes in production needs dynamically. With the rise of cloud computing, MRP systems are also becoming more accessible and scalable, making it easier for businesses of all sizes to harness their potential.

As businesses continue to seek ways to optimize efficiency and respond to customer needs, MRP will play a crucial role in shaping smarter, more agile production processes.

How KnoWerX Can Help You Master Material Requirement Planning?

KnoWerX, a leading institute in supply chain management, offers a specialized course called Certified Direct Material Planner (CDMP). This program is designed to give you a deep understanding of Material Requirement Planning (MRP), equipping you with practical skills to optimize inventory, streamline production processes, and improve overall efficiency. By enrolling in the CDMP course, you’ll gain valuable insights and hands-on experience that can directly enhance your expertise in material planning, setting you up for success in a dynamic and competitive field.

FAQs: Frequently Asked Questions

What is Material Requirement Planning (MRP)?

Material Requirement Planning (MRP) is a systematic approach to ensure the availability of materials and components needed for production, using data from sales forecasts, inventory levels, and production schedules.

What are the key benefits of Material Requirement Planning?

MRP reduces inventory costs, improves production scheduling, enhances customer satisfaction, boosts overall efficiency, and supports data-driven decision-making.

How does Material Requirement Planning improve operational efficiency?

MRP streamlines processes by automating planning, reducing manual effort, and ensuring materials are available when needed, minimizing production delays and waste.

What challenges can businesses face when implementing MRP?

Challenges include ensuring data accuracy, managing the complexity of MRP systems, and integrating MRP with existing inventory and production management tools.

How can KnoWerX help with Material Requirement Planning?

KnoWerX offers the Certified Direct Material Planner (CDMP) course, providing in-depth knowledge of MRP and practical skills to optimize inventory and streamline production processes.

End Notes

Material Requirement Planning is more than a management tool—it’s a strategy that transforms how businesses handle inventory, schedule production, and satisfy customer demands. By reducing inventory costs, enhancing scheduling accuracy, and boosting overall efficiency, MRP empowers companies to stay competitive in today’s demanding market. For companies looking to streamline their production, lower costs, and improve reliability, investing in an MRP system is a smart step toward a more efficient and successful future.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.