Importance of Demand Forecasting for a Resilient Supply Chain

In today’s fast-evolving and often unpredictable market, the importance of demand forecasting cannot be overstated. As businesses worldwide face unprecedented volatility, accurate demand forecasting has become an essential tool for keeping supply chains resilient, efficient, and responsive. By predicting future demand, companies can optimize inventory, manage costs, and mitigate potential disruptions that might otherwise jeopardize operations.

In this article, we will explore the significance of demand forecasting, its role in enhancing supply chain resilience, and how modern technology is taking these predictions to the next level. Understanding the importance of demand forecasting equips businesses to remain competitive, maintain customer satisfaction, and ensure that supply chains are always one step ahead.

The Importance of Demand Forecasting in Supply Chain Management

Understanding and Meeting Customer Demand

At the heart of any successful business is the ability to understand and meet customer demand effectively. This is where the importance of demand forecasting becomes apparent. By accurately predicting future customer needs, businesses can prepare for demand spikes, avoid product shortages, and ensure they are producing enough to satisfy market requirements without overextending resources. Demand forecasting provides a roadmap for companies, enabling them to stay in sync with customer needs and preferences.

For example, retail companies rely heavily on seasonal trends and holiday sales forecasts to anticipate inventory needs. Similarly, manufacturers use demand forecasts to schedule production runs, ensuring they meet demand without causing delays or backlogs in the supply chain. The importance of demand forecasting here lies in its ability to support smooth and efficient operations, allowing companies to stay agile and responsive.

Optimizing Inventory Management

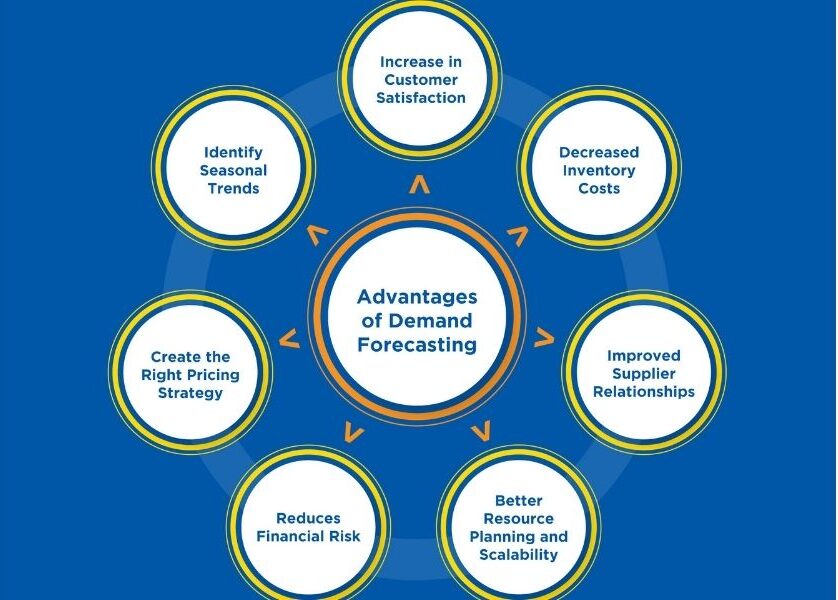

The importance of demand forecasting is also reflected in its impact on inventory management. When businesses have a clear picture of upcoming demand, they can maintain optimal stock levels, reducing the risk of both overstocking and understocking. Effective inventory management means fewer costs tied up in unsold goods and reduced warehousing expenses, which is critical for businesses looking to enhance their bottom line.

By forecasting demand, companies can reduce unnecessary storage costs, freeing up capital that would otherwise be locked in excess inventory. For many businesses, this means less risk of cash flow constraints, especially in industries with tight margins. Demand forecasting allows businesses to allocate resources efficiently, improving both financial performance and operational effectiveness.

Enhancing Resilience in Supply Chains

Adapting to Market Fluctuations

One of the most compelling reasons behind the importance of demand forecasting is its ability to help businesses adapt to sudden market changes. Unforeseen events like economic downturns, supply chain disruptions, or natural disasters can significantly impact demand patterns. With demand forecasting, businesses can anticipate and respond to these fluctuations by adjusting production schedules, altering order quantities, and communicating proactively with suppliers.

The COVID-19 pandemic highlighted the need for resilient supply chains capable of adjusting to extreme shifts in demand. Many companies that invested in robust demand forecasting systems were able to pivot quickly and adapt, minimizing the negative impact on their supply chains. This ability to remain flexible and responsive under pressure underscores the importance of demand forecasting in fostering supply chain resilience.

Reducing Lead Times

Demand forecasting helps businesses reduce lead times by providing a clear view of future needs. This enables companies to plan procurement and production schedules more accurately, aligning supply chain activities with expected demand. Reduced lead times mean faster response to customer orders, more efficient order fulfillment, and ultimately, improved customer satisfaction.

When companies can predict demand accurately, they can also minimize stockouts and overstock situations, which helps in maintaining an efficient supply chain. By reducing the likelihood of order delays or prolonged wait times, demand forecasting enhances the overall customer experience, which is critical for customer retention and loyalty.

Strategic Advantages of Demand Forecasting

Informed Decision-Making

The importance of demand forecasting extends beyond operations; it’s a strategic tool that informs decision-making across the organization. By using data-driven demand forecasts, companies can make more informed choices on resource allocation, workforce planning, and capital expenditures. This helps align business goals with market realities, reducing risk and enhancing performance.

Demand forecasting provides actionable insights that can shape business strategies at multiple levels. For instance, in product development, accurate demand predictions can inform design and innovation decisions based on anticipated customer interest. In marketing, demand forecasts guide promotional efforts, ensuring campaigns align with expected demand and that marketing budgets are optimized for peak periods.

Coordinating Sales and Marketing with Demand

Effective demand forecasting enables closer alignment between sales, marketing, and supply chain operations. When sales and marketing teams have access to demand forecasts, they can tailor campaigns to match forecasted demand, reducing the risk of overwhelming supply chains with unexpected surges in orders. This alignment fosters collaboration and ensures that business departments work toward a common goal.

For instance, a product launch backed by demand forecasts allows companies to scale up production in advance, minimizing the risk of stockouts or long lead times. This integrated approach supports a more synchronized, efficient supply chain that consistently meets customer expectations, demonstrating the importance of demand forecasting for cohesive business operations.

Key Methods in Demand Forecasting

Qualitative Forecasting Techniques

Qualitative methods rely on expert judgment, market research, and subjective insights, making them useful for new products or in markets with limited historical data. Techniques like expert panels, market surveys, and the Delphi method are common in qualitative demand forecasting. These approaches provide valuable insights and can complement quantitative data when historical records are sparse.

Quantitative Forecasting Models

Quantitative forecasting uses historical data to identify trends and make future predictions. Time series analysis, econometric modelling, and causal models are commonly used quantitative techniques. These models are invaluable for companies in mature markets where demand patterns are established, allowing for high levels of accuracy in forecasting.

Collaborative Forecasting

Collaborative demand forecasting involves gathering input from multiple stakeholders—suppliers, internal departments, and even customers—to create a holistic view of anticipated demand. By pooling insights from different perspectives, companies can build a more reliable and comprehensive forecast that serves the entire supply chain effectively.

The Role of Technology in Demand Forecasting

Advanced Analytics and Artificial Intelligence

As technology advances, the importance of demand forecasting is magnified by tools like artificial intelligence (AI) and machine learning. These technologies allow for real-time data processing, detecting patterns that inform highly accurate demand forecasts. AI-driven forecasting enables businesses to refine their predictions continually, adapting to new information and trends as they emerge.

Leveraging Big Data and Predictive Analytics

Predictive analytics is another transformative tool in demand forecasting. By integrating data from diverse sources—such as social media trends, customer feedback, and economic indicators—predictive analytics generates actionable forecasts that help companies stay ahead of demand. This use of big data to predict market behaviour adds a proactive element to demand forecasting, further reinforcing its importance for building resilient, data-driven supply chains.

FAQs: Frequently Asked Questions

What is demand forecasting in supply chain management?

Demand forecasting is the process of predicting future customer demand using historical data, market trends, and advanced analytics. It helps businesses plan inventory, production, and procurement, ensuring smooth and efficient supply chain operations.

How does demand forecasting enhance supply chain resilience?

Demand forecasting enhances supply chain resilience by enabling businesses to adapt quickly to market changes, manage inventory efficiently, and reduce lead times. It ensures supply chains remain responsive to unexpected disruptions or demand fluctuations.

What are the key methods of demand forecasting?

The primary methods of demand forecasting include:

- Qualitative techniques (expert judgment, market surveys).

- Quantitative models (time series analysis, econometric models).

- Collaborative forecasting (involving stakeholders like suppliers and customers)

How does technology improve demand forecasting?

Technologies like artificial intelligence, machine learning, and predictive analytics refine demand forecasting by processing real-time data, identifying patterns, and generating accurate predictions. These tools enhance decision-making and operational efficiency.

How can KnoWerX help with demand forecasting?

KnoWerX offers the Certified Forecasting and Demand Management (CFDM) program, equipping professionals with the skills to implement effective demand forecasting strategies. It prepares businesses to optimize supply chains and stay competitive in dynamic markets.

End Notes

At KnoWerX, we understand that in today’s competitive, fast-paced market, the importance of demand forecasting is crucial for any business seeking a resilient and responsive supply chain. Accurate demand forecasting empowers companies to anticipate customer needs with precision, optimize inventory, and make informed strategic decisions that keep them aligned with future demand trends. As technology continues to refine forecasting capabilities, the ability to foresee demand shifts and adapt swiftly offers a powerful competitive edge.

Investing in a robust demand forecasting process through KnoWerX’s Certified Forecasting and Demand Management (CFDM) program goes beyond operational efficiency; it’s about fostering sustainable growth and building long-term resilience. Our CFDM certification equips professionals with the skills and expertise needed to harness the true potential of demand forecasting, preparing businesses to thrive amid uncertainty. With KnoWerX, companies don’t just recognize the importance of demand forecasting—they leverage it as a cornerstone for future-ready supply chain excellence.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.