Causes of Supply Chain Disruptions & How to Overcome Them

Supply chain disruptions are a pressing concern for businesses worldwide. They create significant challenges, such as delays, increased costs, and customer dissatisfaction, affecting the overall efficiency of operations. Understanding the nature of supply chain disruptions, their causes, and the strategies to overcome them is vital for ensuring business continuity.

What Is Supply Chain Disruption?

Supply chain disruption occurs when the smooth flow of goods, services, or information across the supply chain is interrupted due to unforeseen circumstances. These disruptions can happen at any point—sourcing raw materials, manufacturing, warehousing, or final delivery to customers.

For instance, a delay caused by a shipment being held at customs or a shortage of raw materials due to geopolitical tensions can lead to significant operational slowdowns. The ripple effect of such disruptions can harm a business’s reputation, lead to financial losses, and affect customer relationships

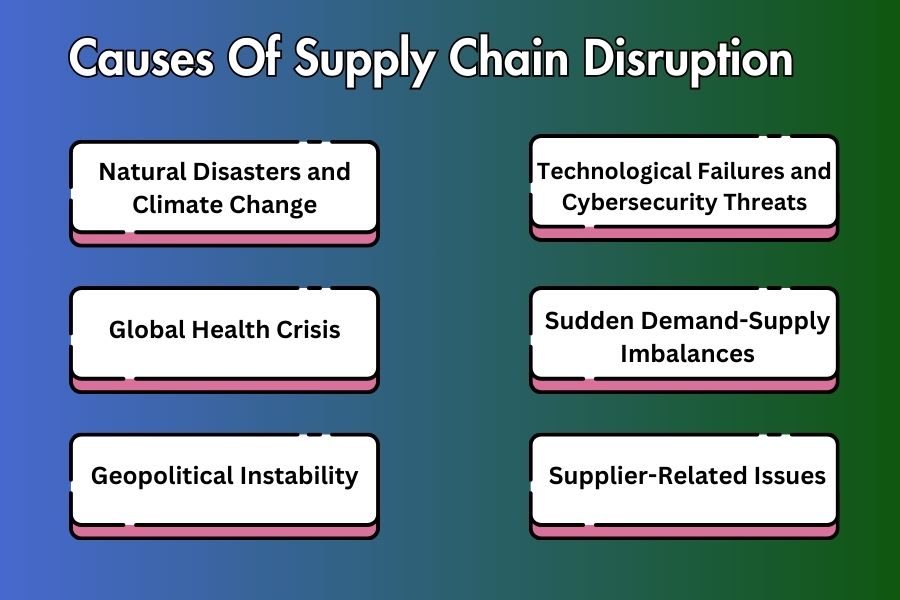

What Are the Leading Causes of Supply Chain Disruptions?

The causes of supply chain disruptions are diverse, ranging from natural events to human-induced challenges:

Natural Disasters and Climate Change

Floods, earthquakes, hurricanes, and other natural events can destroy critical infrastructure and disrupt transportation routes. The increasing frequency of extreme weather events due to climate change has heightened these risks.

Global Health Crises

The COVID-19 pandemic exposed vulnerabilities in global supply chains, leading to factory closures, transportation delays, and labour shortages. Health crises often impact every stage of the supply chain.

Geopolitical Instability

Trade wars, economic sanctions, and political unrest can create barriers to sourcing raw materials or accessing markets, impacting production and logistics.

Technological Failures and Cybersecurity Threats

Modern supply chains heavily rely on technology for operations like inventory management and logistics tracking. Cyberattacks or system outages can cause significant disruptions.

Sudden Demand-Supply Imbalances

Unexpected spikes or drops in demand, driven by trends, economic conditions, or seasonal factors, can lead to either excess inventory or shortages.

Supplier-Related Issues

Dependency on a single supplier or inadequate supplier vetting increases vulnerability. Supplier bankruptcy or production delays can create bottlenecks.

How Can Businesses Overcome Supply Chain Disruptions?

Addressing supply chain disruptions requires strategic planning and a proactive approach. Here are effective methods to minimize their impact:

Leverage Technology for Visibility

Technologies like artificial intelligence (AI), machine learning, and blockchain provide real-time insights and predictive analytics to identify potential issues early.

Diversify Suppliers and Geographies

Engaging multiple suppliers and sourcing from varied locations reduces reliance on a single source and mitigates risks posed by localized disruptions.

Develop Contingency Plans

Regular risk assessments and robust contingency planning ensure businesses can quickly pivot during disruptions. For instance, having backup suppliers or alternative shipping routes can minimize delays.

Adopt Agile and Lean Practices

Agile supply chain models enable businesses to adapt rapidly to changing circumstances. Lean practices, such as maintaining optimal inventory levels, ensure flexibility without overstocking.

Invest in Workforce Training

A well-trained workforce capable of using advanced technologies and executing contingency plans efficiently strengthens the organization’s ability to respond to disruptions.

Collaborate Across the Supply Chain

Open communication and collaboration with suppliers, logistics partners, and customers foster trust and enhance problem-solving during challenging times.

How can KnoWerX’s SCRR (Supply Chain Risk and Resiliency Certificate) Help face supply chain disruption?

In an era of increasing uncertainties, businesses must be prepared to handle risks effectively. KnoWerX, a leading supply chain management institute, offers the Supply Chain Risk and Resiliency (SCRR) Certificate to empower professionals and organizations with the tools to mitigate disruptions.

Comprehensive Training in Risk Management

The SCRR certification program covers essential aspects of identifying, assessing, and managing supply chain risks. Participants learn about proactive measures to tackle disruptions and safeguard operations.

Focus on Resiliency Building

The program emphasizes building resilient supply chains through strategies like supplier diversification, risk-sharing agreements, and the adoption of robust technologies.

Expert-Led Insights and Case Studies

The course includes real-world case studies and insights from industry experts, helping professionals understand practical solutions to complex supply chain challenges.

Improved Decision-Making Capabilities

By learning to analyse and predict potential risks, certified professionals can make informed decisions that enhance operational efficiency and reduce vulnerabilities.

Recognition of Industry Standards

SCRR certification aligns with global supply chain standards, ensuring that participants are equipped with skills relevant to the international market.

KnoWerX’s SCRR certification not only prepares individuals to address current challenges but also helps them future-proof their supply chains against evolving risks.

Why Is Leadership Important in Managing Supply Chain Disruptions?

Leadership plays a critical role in overcoming supply chain disruptions by guiding teams and fostering resilience. Here’s how strong leadership can make a difference:

Promoting a Culture of Adaptability

Effective leaders encourage innovation and flexibility, ensuring teams are prepared to adapt to unexpected changes.

Facilitating Transparent Communication

Open communication with stakeholders, suppliers, and customers ensures that everyone is aligned and working towards common solutions.

Providing Strategic Direction

Leaders help align supply chain strategies with organizational goals, ensuring disruptions are managed in ways that minimize long-term impact.

Encouraging Collaboration and Innovation

Leaders can create more resilient and efficient supply chains by fostering partnerships and investing in new technologies.

FAQs: Frequently Asked Questions

What is a supply chain disruption?

Supply chain disruption refers to an interruption in the smooth flow of goods, services, or information across the supply chain, caused by unforeseen circumstances like natural disasters, geopolitical instability, or technology failures.

What are the common causes of supply chain disruptions?

Key causes include natural disasters, global health crises, geopolitical instability, technological failures, demand-supply imbalances, and supplier-related issues.

How can businesses overcome supply chain disruptions?

Strategies include leveraging technology, diversifying suppliers, developing contingency plans, adopting agile practices, investing in workforce training, and collaborating with supply chain partners.

Why is leadership important in managing supply chain disruptions?

Leadership fosters adaptability, transparent communication, strategic direction, and collaboration, ensuring teams are prepared to respond effectively to disruptions.

How does KnoWerX's SCRR certification help manage supply chain risks?

KnoWerX's Supply Chain Risk and Resiliency (SCRR) certification provides training in risk identification, resiliency building, decision-making, and adherence to global standards to help professionals tackle supply chain disruptions effectively.

End Notes

Supply chain disruptions are inevitable, but businesses can navigate them effectively by understanding their causes and adopting robust strategies. Leveraging technology, diversifying suppliers, and building resiliency are key steps toward minimizing risks.

KnoWerX’s SCRR certification empowers professionals with the knowledge and skills needed to manage disruptions efficiently. By investing in training and strong leadership, businesses can build agile supply chains that thrive despite challenges, ensuring long-term success and customer satisfaction.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.