What is Supply Chain Visibility and Its Critical Importance?

Supply chain management is a critical element of modern business operations, ensuring goods and services move seamlessly from production to consumption. Within this framework, supply chain visibility (SCV) has emerged as a game-changer, helping organizations stay agile and competitive in an ever-changing global market. It is no longer just about moving goods; it’s about gaining real-time insight into every part of the process to make data-driven decisions and respond proactively to challenges.

The importance of SCV has grown significantly with the increasing complexity of global supply chains. Businesses today face challenges such as fluctuating demand, geopolitical uncertainties, and the need to adapt quickly to changing market dynamics. Supply chain visibility not only helps businesses address these challenges but also creates a competitive edge by improving efficiency, reducing risks, and enhancing customer satisfaction.

What is Supply Chain Visibility?

Supply chain visibility refers to the ability to track, monitor, and manage the movement of goods, data, and resources across the entire supply chain. It involves integrating various technologies, processes, and systems to provide real-time, end-to-end insights into supply chain activities.

In practical terms, SCV ensures that companies know the location and status of their goods at every stage—whether they are in production, transit, or storage. This visibility is crucial for identifying potential issues, optimizing workflows, and maintaining transparency with stakeholders, including suppliers, logistics providers, and customers.

SCV goes beyond physical tracking. It includes financial transactions, inventory levels, and supplier performance metrics. For example, a retailer might use SCV to check stock levels in a warehouse, track incoming shipments from suppliers, and forecast demand for the upcoming season—all in real-time.

The rise of digital technologies, such as IoT devices, blockchain, and AI, has made achieving supply chain visibility easier than ever. However, it also comes with challenges, such as data integration and managing the complexity of global supply chains, which businesses must address to unlock SCV’s full potential.

Goals of Supply Chain Visibility

The objectives of Supply Chain Visibility extend beyond simply tracking goods; they aim to create a responsive, efficient, and risk-resilient supply chain. Below are the primary goals of supply chain visibility:

1. Enhancing Transparency

Transparency is the cornerstone of effective supply chain management. SCV ensures that all stakeholders, including suppliers, manufacturers, logistics providers, and customers, have access to accurate, real-time information. This transparency reduces misunderstandings, fosters trust, and facilitates seamless collaboration across the supply chain.

2. Optimizing Operations

Visibility into every stage of the supply chain allows businesses to identify inefficiencies, such as delays in production, inventory mismanagement, or logistical bottlenecks. By addressing these issues promptly, companies can reduce costs, minimize waste, and streamline their operations.

3. Mitigating Risks

Global supply chains are exposed to numerous risks, including natural disasters, geopolitical tensions, supplier failures, and demand fluctuations. SCV helps companies proactively identify these risks and implement contingency plans, ensuring business continuity.

4. Improving Decision-Making

Supply chain visibility provides actionable insights that support data-driven decision-making. Whether it’s choosing a reliable supplier, optimizing inventory levels, or responding to market trends, SCV enables businesses to make informed choices.

5. Enhancing Customer Satisfaction

Customers today expect greater transparency in their transactions, including updates on the status and location of their orders. SCV ensures that businesses can meet these expectations, leading to improved customer trust and loyalty.

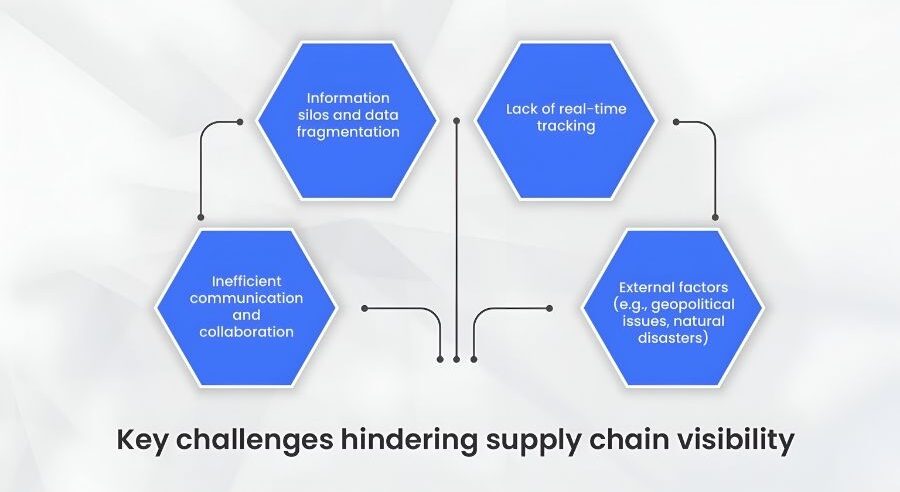

What Are the Problems and Solutions in Supply Chain Visibility?

Achieving full visibility in supply chain operations is challenging due to various factors. Below are some common problems and their potential solutions:

Supply Chain Visibility Problems

Data Silos

Different departments within an organization often use disconnected systems that do not communicate effectively. This fragmentation creates data silos, preventing the seamless flow of information across the supply chain.

Lack of Standardization

Inconsistencies in data formats and reporting methods among different suppliers, logistics providers, and partners make it difficult to integrate and analyze information.

Complex Global Operations

Managing a global supply chain involves dealing with diverse regulations, languages, currencies, and time zones. This complexity adds layers of difficulty to achieving end-to-end visibility.

Limited Technology Adoption

Many businesses, especially small and medium-sized enterprises (SMEs), lack access to advanced technologies such as IoT, blockchain, and predictive analytics, which are essential for SCV.

Data Overload

With the increasing use of IoT devices, sensors, and automated systems, companies generate vast amounts of data. Without the right tools and expertise, managing and analyzing this data can be overwhelming.

Supply Chain Visibility Solutions

Integrating Advanced Technologies

Adopting technologies such as the Internet of Things (IoT), artificial intelligence (AI), blockchain, and machine learning can provide real-time insights and enhance data accuracy. IoT sensors, for instance, can track shipments, monitor inventory, and provide real-time updates on transportation.

Using Cloud-Based Platforms

Cloud technology facilitates seamless data sharing and collaboration among stakeholders, regardless of their location. It also supports scalability and ensures data security.

Implementing Standardized Processes

Developing standardized protocols for data collection, reporting, and analysis ensures consistency and simplifies integration across the supply chain.

Leveraging Data Analytics

Advanced analytics tools can process large volumes of data to uncover patterns, predict disruptions, and provide actionable insights. Predictive analytics, for example, can forecast demand fluctuations and help businesses plan accordingly.

Building Strong Partnerships

Collaboration with suppliers, logistics providers, and other partners ensures alignment and improves data sharing. Establishing clear communication channels and mutual trust is crucial for achieving visibility.

What Are the Types of Supply Chain Visibility?

Supply chain visibility encompasses various aspects of the supply chain, each contributing to a comprehensive understanding of operations.

1. Inventory Visibility

Inventory visibility ensures that businesses can track stock levels across all locations, including warehouses, retail outlets, and in-transit shipments. This helps prevent overstocking, stockouts, and excessive carrying costs.

2. Transportation Visibility

Transportation visibility focuses on monitoring the movement of goods in real-time. By tracking shipments, businesses can optimize delivery routes, reduce delays, and provide accurate delivery timelines to customers.

3. Order Visibility

Order visibility allows both businesses and customers to track the status of orders, from placement to delivery. This transparency builds customer trust and enhances the shopping experience.

4. Supplier Visibility

Supplier visibility involves monitoring the activities and performance of suppliers. It helps ensure timely delivery of raw materials, adherence to quality standards, and overall reliability.

5. Financial Visibility

Financial visibility ensures transparency in payment processes, budgeting, and cost tracking. It helps businesses manage cash flow effectively and avoid financial discrepancies.

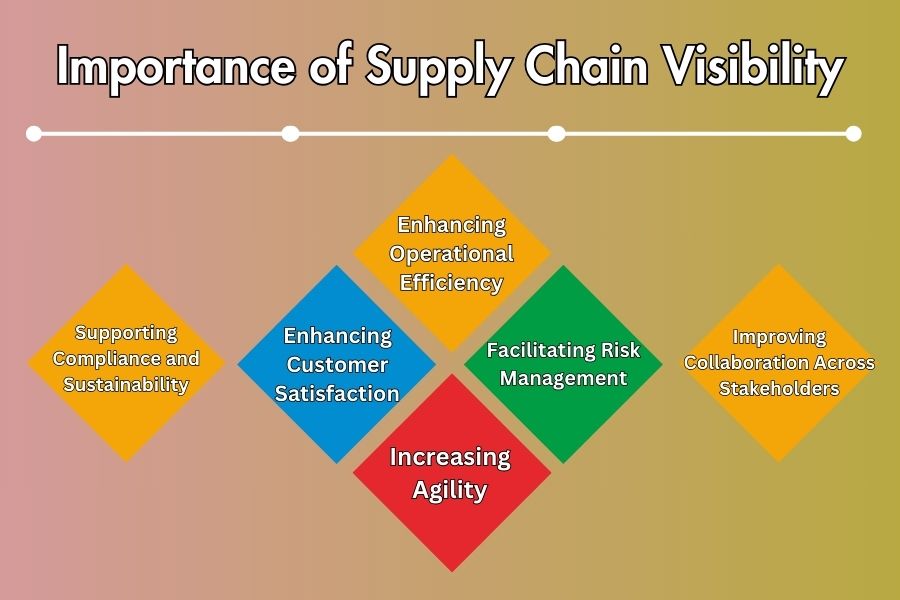

Importance of Supply Chain Visibility

Supply chain visibility is critical to a business’s success and efficiency. It extends benefits across multiple domains, from operational efficiency to customer satisfaction. Below, we explore the importance of supply chain visibility.

1. Enhancing Operational Efficiency

SCV allows businesses to monitor their supply chain processes in real time. By identifying bottlenecks, inefficiencies, or disruptions, companies can take corrective actions promptly. For example:

Reducing Lead Times: Visibility helps streamline processes, ensuring faster delivery and reduced wait times.

Minimizing Waste: By tracking inventory and production, businesses can avoid overproduction and excess stock.

Improving Resource Utilization: SCV helps allocate resources more effectively by aligning supply with demand.

2. Facilitating Risk Management

Global supply chains face numerous risks, such as delays due to weather conditions, geopolitical conflicts, and supplier failures. SCV provides early warnings about potential risks, allowing businesses to:

Develop Contingency Plans: Have alternative suppliers or routes ready in case of disruptions.

Proactively Address Issues: Spot issues like delayed shipments or raw material shortages before they escalate.

3. Increasing Agility

Markets are unpredictable, and customer preferences change rapidly. SCV equips businesses with the flexibility to adapt to these changes. For instance:

Demand Fluctuations: Companies can adjust production levels or reallocate inventory based on real-time demand insights.

Supply Adjustments: Visibility ensures quicker sourcing of materials in case of unexpected surges in demand.

4. Enhancing Customer Satisfaction

Modern customers expect transparency and quick updates about their orders. SCV supports this by:

Real-Time Tracking: Customers can track their orders from placement to delivery, enhancing trust.

On-Time Deliveries: By monitoring transportation and inventory, businesses can ensure timely deliveries.

Personalized Services: Visibility into customer preferences allows businesses to offer tailored solutions.

5. Supporting Compliance and Sustainability

Industries such as pharmaceuticals, food, and electronics often have strict regulatory requirements. SCV ensures:

Regulatory Compliance: Complete traceability of goods ensures adherence to industry standards.

Sustainability: Businesses can monitor their carbon footprint, reduce waste, and source materials responsibly.

6. Improving Collaboration Across Stakeholders

Supply chains involve multiple stakeholders, including suppliers, manufacturers, logistics providers, and retailers. SCV fosters collaboration by ensuring all parties have access to accurate and timely data. This leads to:

Stronger Partnerships: Increased trust and alignment among stakeholders.

Reduced Communication Gaps: Streamlined information sharing eliminates misunderstandings.

How to Increase Supply Chain Visibility?

Increasing supply chain visibility requires a strategic approach and the implementation of advanced tools and technologies. Here are some key steps:

Adopt IoT and Blockchain Technology

IoT devices, such as sensors and RFID tags, provide real-time tracking of goods, while blockchain ensures data integrity and traceability across the supply chain.

Invest in Data Analytics

Data analytics tools can process vast amounts of information to provide actionable insights, identify inefficiencies, and predict potential disruptions.

Collaborate with Partners

Establishing strong relationships with suppliers, logistics providers, and distributors ensures better data sharing and alignment across the supply chain.

Use Cloud-Based Solutions

Cloud platforms enable seamless communication and collaboration among all stakeholders, improving accessibility and data sharing.

Train Employees

Educating employees about the importance of SCV and how to use advanced tools effectively is essential for maximizing the benefits of visibility initiatives.

Supply Chain Visibility Examples

1. Retail Industry

Companies like Amazon and Walmart use SCV to provide customers with real-time updates on their orders, ensuring timely deliveries and enhancing customer satisfaction.

2. Healthcare

SCV in the healthcare industry ensures the timely delivery of critical supplies, such as medicines and vaccines, while maintaining compliance with safety and quality standards.

3. Automotive Industry

Automotive companies use SCV to track the movement of parts and components across suppliers, ensuring efficient production schedules and minimizing delays.

4. Food and Beverage

In the food industry, SCV helps monitor the freshness of perishable goods and ensures compliance with food safety regulations during transportation and storage.

How KnoWerX Can Help Supply Chain Professionals?

KnoWerX is a leading supply chain management institute dedicated to empowering professionals with the skills and knowledge required to excel in the dynamic supply chain industry. Through its comprehensive training and certification programs, KnoWerX provides the tools to enhance supply chain visibility and optimize operations.

1. Specialized Training Programs

KnoWerX offers tailored courses that address the critical aspects of supply chain management, including supply chain visibility. These programs focus on:

Real-World Applications: Practical insights into leveraging technology for improved visibility.

Advanced Tools Training: Guidance on using software solutions like ERP and TMS for real-time tracking and analytics.

2. Globally Recognized Certifications

KnoWerX provides globally recognized certifications such as APICS, CPIM, and CSCP, which are highly valued in the industry. These certifications enable professionals to:

Stay updated with the latest trends and techniques.

Enhance their credentials and marketability in the supply chain field.

3. Industry-Experienced Faculty

The institute’s faculty consists of industry experts who bring years of practical experience to the classroom. Their insights help participants gain an in-depth understanding of challenges like supply chain visibility and its solutions.

4. Networking Opportunities

KnoWerX facilitates connections with other professionals and organizations in the supply chain sector. This network is invaluable for sharing knowledge, discussing industry trends, and exploring collaborative solutions to visibility challenges.

5. Focus on Future-Ready Skills

With a focus on emerging technologies like AI, IoT, and blockchain, KnoWerX ensures professionals are equipped to handle future advancements in supply chain management, including enhanced visibility and transparency.

For supply chain professionals aiming to improve their expertise and contribute to their organization’s efficiency, KnoWerX provides the foundation to succeed in today’s competitive market.

FAQs: Frequently Asked Questions

What is supply chain visibility (SCV)?

Supply chain visibility refers to the ability to track and monitor goods, data, and resources throughout the supply chain in real-time. It ensures transparency, efficiency, and proactive risk management.

Why is supply chain visibility important?

SCV enhances operational efficiency, mitigates risks, improves customer satisfaction, and supports compliance. It helps businesses respond quickly to market changes and maintain a competitive edge.

What are the main goals of supply chain visibility?

The primary goals include improving transparency, optimizing operations, mitigating risks, enabling data-driven decisions, and enhancing customer satisfaction.

What are the common challenges in achieving supply chain visibility?

Challenges include data silos, lack of standardization, complex global operations, limited technology adoption, and data overload.

How can KnoWerX help in improving supply chain visibility?

KnoWerX offers specialized training, certifications, and expertise in supply chain management, equipping professionals with the tools to implement effective SCV solutions.

End Notes

At KnoWerX, we believe that supply chain visibility (SCV) is no longer an optional advantage but a critical necessity for businesses navigating today’s complex and competitive landscape. SCV provides real-time insights that enable organizations to streamline processes, minimize costs, and enhance customer satisfaction—cornerstones of effective supply chain management.

Achieving SCV requires a strategic approach, including investments in advanced technologies, fostering collaboration among stakeholders, and implementing standardized processes. Industries like retail, healthcare, and automotive demonstrate how SCV can transform operations, ensuring resilience, transparency, and sustained success.

As a leader in supply chain education and training, KnoWerX equips professionals and organizations with the knowledge and tools to implement and leverage SCV effectively. We are committed to helping businesses build robust, future-ready supply chains capable of thriving in an interconnected world.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.