What is Supply Chain Operations Reference? Boost your Supply Chain Efficiency

The Supply Chain Operations Reference (SCOR) model is an essential framework for businesses that want to improve their supply chain performance. It provides a structured approach to analysing and optimizing supply chain processes, making them more efficient and productive. Developed by the Supply Chain Council, the SCOR model is widely adopted across industries because it offers a standard for evaluating supply chains and identifying areas for improvement.

In this article, we’ll break down the SCOR model, its importance, and tips for using it effectively. Additionally, we’ll explore how you can enhance your understanding through a specialized SCOR course.

What is the Purpose of the Supply Chain Operations Reference (SCOR) Model?

The primary purpose of the SCOR model is to help businesses manage and improve their supply chain operations. It provides a common language for companies to evaluate their supply chain activities, ensuring that everyone involved is on the same page. The model covers a wide range of processes, from planning and sourcing to delivery and returns, allowing businesses to assess the entire supply chain lifecycle.

It helps companies by:

- Standardizing processes – The SCOR model creates consistency across departments by defining processes and performance metrics that everyone can understand and follow.

- Improving communication – Since the model is a global standard, it bridges communication gaps between suppliers, customers, and partners.

- Benchmarking performance – SCOR provides a way to measure performance using standard metrics, enabling companies to see how they compare with industry standards.

- Identifying inefficiencies – With SCOR, businesses can pinpoint bottlenecks, delays, or underperforming areas in their supply chain and develop strategies to improve them.

How Does the Supply Chain Operations Reference (SCOR) Model Work?

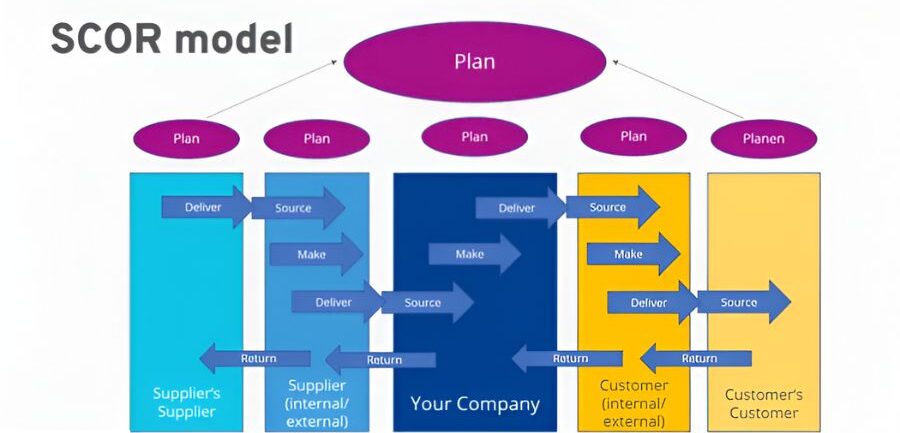

The Supply Chain Operations Reference (SCOR) model operates by breaking down the supply chain into five primary processes:

- Plan – This stage involves forecasting demand, balancing supply with demand, and planning for resources. Effective planning ensures that the right products are available at the right time.

- Source – Sourcing focuses on procuring raw materials, selecting suppliers, and managing supplier relationships. A reliable sourcing process ensures that the materials needed for production are available when required.

- Production – This stage deals with production and manufacturing. It covers the transformation of raw materials into finished goods, ensuring that products meet quality standards and are produced efficiently.

- Deliver – Delivery is about getting the finished product to customers. It includes order management, transportation, and distribution, ensuring that products reach customers on time and in good condition.

- Return – The final process focuses on handling returns, repairs, and maintenance. Efficient return processes help maintain customer satisfaction and minimize waste.

Each of these processes is further divided into sub-processes, making it easier to analyse and optimize every aspect of the supply chain.

Why is the Supply Chain Operations Reference (SCOR) Model Important for Businesses?

The Supply Chain Operations Reference (SCOR) model’s importance lies in its ability to streamline supply chain operations, leading to better overall performance. Here are some reasons why it is vital for businesses:

- Enhanced Efficiency – By following the SCOR model, companies can reduce waste, minimize delays, and streamline operations. This results in faster production times, lower costs, and improved customer satisfaction.

- Cost Savings – The model helps businesses identify areas where costs can be reduced, such as minimizing excess inventory, optimizing transportation routes, or renegotiating supplier contracts.

- Risk Management – SCOR helps companies anticipate and plan for potential disruptions in the supply chain, such as supplier issues or changes in demand. This allows for proactive risk management.

- Continuous Improvement – The SCOR model encourages continuous monitoring and improvement. Businesses can use the model to track performance, benchmark against industry standards, and make incremental changes that lead to long-term improvements.

How Can You Implement the SCOR Model?

Implementing the Supply Chain Operations Reference (SCOR) model may seem daunting at first, but following these steps can simplify the process:

- Assess Your Current Supply Chain – Start by evaluating your existing supply chain processes. Identify the strengths, weaknesses, and areas that need improvement. You can use SCOR’s predefined metrics to measure performance.

- Map Your Supply Chain – Create a detailed map of your supply chain, covering all the key processes from planning to returns. This will help you visualize the entire operation and identify bottlenecks.

- Set Clear Goals – Based on your assessment, set measurable goals for each stage of the supply chain. For instance, you may aim to reduce lead times, improve supplier performance, or decrease costs.

- Collaborate with Stakeholders – Effective implementation of the SCOR model requires collaboration with suppliers, customers, and internal teams. Ensure that everyone is aligned with the goals and understands their role in the process.

- Monitor and Improve – Continuously monitor the performance of your supply chain against the SCOR metrics. Use this data to make adjustments and drive continuous improvement.

What are the Benefits of Taking a SCOR Course?

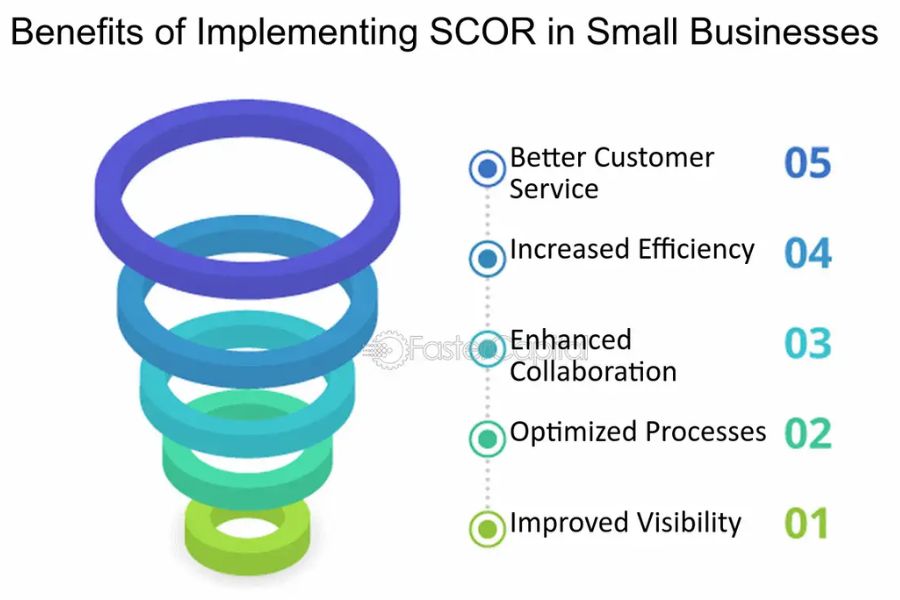

To fully leverage the Supply Chain Operations Reference (SCOR) model, businesses often benefit from specialized training. A SCOR course helps you gain deeper insights into the framework and teaches you how to apply it effectively in real-world scenarios. By enrolling in a SCOR course, you will:

- Learn from Industry Experts – SCOR courses are taught by supply chain professionals with extensive experience. You’ll gain practical knowledge that you can apply directly to your business.

- Understand Advanced Concepts – A SCOR course goes beyond the basics, delving into advanced topics like performance metrics, supply chain strategy, and risk management.

- Get Hands-on Practice – Many SCOR courses offer case studies, exercises, and real-world simulations, allowing you to practice what you learn in a controlled environment.

- Improve Your Career Prospects – Earning a SCOR certification can boost your career in supply chain management. It demonstrates to employers that you have the skills and knowledge to optimize supply chain operations.

SCOR DS (Digital Standard)

SCOR DS (Digital Standard) is an advanced version of the traditional SCOR model, tailored for the digital age. It focuses on integrating digital technologies such as data analytics, artificial intelligence, and the Internet of Things (IoT) into supply chain processes. This enhanced framework helps businesses not only optimize their physical supply chains but also harness the power of digital tools to drive efficiency and innovation.

The SCOR DS model is particularly relevant today as companies increasingly rely on digital solutions to stay competitive. By applying SCOR DS, businesses can improve visibility across the supply chain, automate repetitive tasks, and make data-driven decisions that enhance performance.

Why Should You Take a SCOR DS Course?

KnoWerX offers a comprehensive SCOR DS course that equips you with the knowledge and skills to implement digital strategies in supply chain management. This course covers essential topics like digital transformation, leveraging data analytics, and optimizing processes using technology. By enrolling in the SCOR DS course, you’ll learn how to apply the latest digital tools to make your supply chain smarter, more efficient, and more adaptable to modern challenges.

With the expertise and guidance of KnoWerX, you’ll be well-prepared to integrate digital standards into your organization’s supply chain, positioning it for long-term success in the digital era.

FAQs: Frequently Asked Questions

What is the Supply Chain Operations Reference (SCOR) model?

The Supply Chain Operations Reference (SCOR) model is a framework developed to help businesses analyze and optimize their supply chain processes, covering areas like planning, sourcing, production, delivery, and returns.

Why is the Supply Chain Operations Reference model important for businesses?

The SCOR model is essential for streamlining supply chains, improving communication, reducing costs, and managing risks more effectively.

What are the five main processes in the Supply Chain Operations Reference model?

The SCOR model is divided into five processes: Plan, Source, Produce, Deliver, and Return, which cover the entire supply chain lifecycle.

What is SCOR DS (Digital Standard)?

SCOR DS is an advanced version of the SCOR model, integrating digital technologies like AI, IoT, and data analytics to further optimize supply chain processes.

Why should I consider a SCOR DS course from KnoWerX?

KnoWerX offers a comprehensive SCOR DS course, equipping professionals with the skills to implement digital strategies and improve supply chain performance using advanced technologies.

End Notes

The Supply Chain Operations Reference model is a powerful tool for improving supply chain performance. It provides a structured approach for businesses to assess and optimize their supply chain processes, leading to better efficiency, cost savings, and risk management. By implementing the SCOR model and enrolling in a SCOR course, businesses can gain a competitive advantage in today’s fast-paced market.

If you’re looking to enhance your supply chain management skills, consider enrolling in a SCOR course from KnoWerX, where you’ll receive expert guidance and practical training to excel in your career.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.